Circular Fire Bricks

Circular fire bricks are cylindrical, barrel or round. They can also be round or combined. Kerui characterizes their overall production as special-shaped refractory brick products. Please see the text for the specific advantages and applications of round fire brick.

- Price Advantage: located in Xinmi, the hometown of refractory materials, with abundant resources and affordable prices.

- After-Sales Advantage: one-on-one tracking service; technical support provided by the chief engineer.

- Supply Advantage: customized bricks are delivered from the kiln in 3-7 days and standard bricks are shipped directly from stock.

Specific Advantages of Circular Fire Bricks

Below are some specific advantages of round refractory bricks. You can also watch more videos about the performance test of Kerui refractory bricks on YouTube.

- High temperature resistance: circular fire bricks are particularly suitable for industrial equipment that requires high temperature operation, such as metallurgy, glass melting and ceramic firing.

- Excellent thermal stability: this type of refractory bricks will not crack and be damaged due to thermal expansion or contraction. Thus, they have a long service life.

- High mechanical strength: like medium duty fire bricks, these bricks have high compressive and flexural strengths. Moreover, they are not easy to break and wear.

- Adaptability of shape and size: the special shape design of round refractory bricks enables them to better adapt to certain specific furnace lining structures and ensure tight splicing. This improves the stability and sealing of the overall structure.

- Versatility: Kerui round fire brick can be customized according to specific needs. Such as adjusting the formula to enhance certain specific properties (such as thermal shock resistance, alkali resistance, etc.).

Application of Circular Fire Bricks in Specific Parts

Circular and wedge fire brick also play a key role in various high temperature environments.

- Converter: used for the lining of the converter, especially the top and wall parts.

- Electric arc furnace: used for the wall and bottom of the electric arc furnace to prevent erosion by molten metal and slag.

- Glass melting furnace: used for the bottom of the melting pool, side walls and the top and arch parts of the melting furnace.

- Kiln head and kiln tail: used for the lining of the kiln head hood and kiln tail hood of the rotary kiln, withstanding high temperature and wear.

- Firing zone: used for the hottest firing zone part of the rotary kiln, withstanding high temperature and chemical corrosion.

- Incinerator: used for the combustion chamber and flue part of the incinerator.

- Boiler: used for the combustion chamber and superheater part of the power boiler.

- Tunnel kiln and roller kiln: used for the lining of the tunnel kiln and roller kiln.

- Intermittent kiln: used for the furnace and wall of the intermittent kiln, withstanding high temperature and frequent thermal cycles.

- Lining for other industrial equipment…

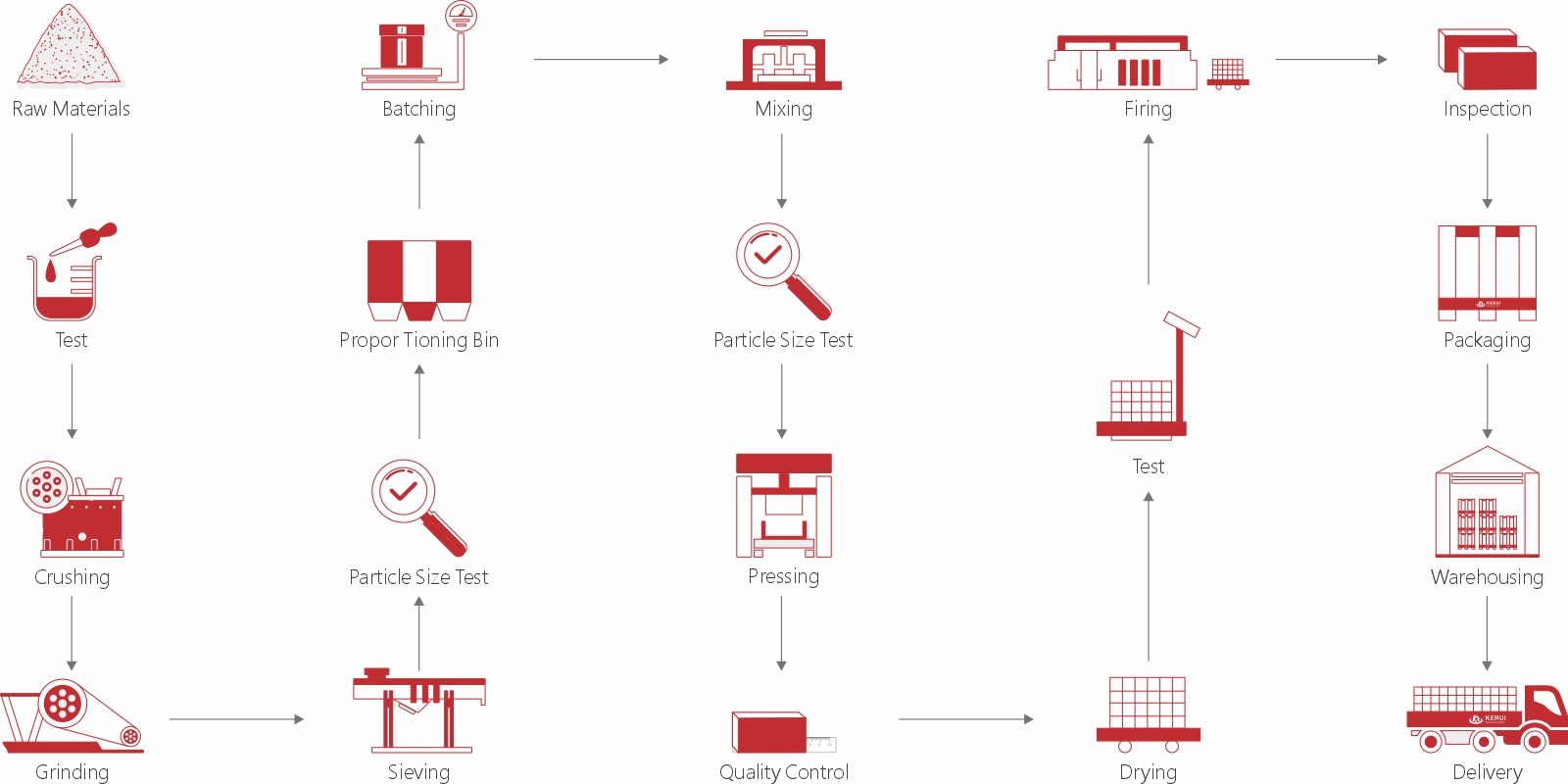

Production Method of Round Fire Brick

The difficulty in the process of producing round refractory bricks lies mainly in forming and sintering. Forming is related to the quantitative size of the mold. Sintering is its transformation from green body to solid dense sintered body. Put the formed green body into a high temperature tunnel kiln for sintering at 1500℃(2732℉). Besides, if the brick mold does not deform or crack after sintering, it proves that the round high temperature refractory brick is a qualified product as a whole.

The most commonly used molding method in the production of Kerui round refractory bricks is machine pressing. Machine pressing has the characteristics of dense green body structure, high strength, small shrinkage during drying and firing and easy size control. In addition, in order to reduce the layer density of the green body, Kerui uses the double-sided pressure molding method to manufacture round refractory bricks.

We can divide the sintering process into three stages: initial, middle and late stages. In the initial stage of sintering, only the heavy particles of the formed body can be rearranged, the voids can be deformed and reduced, but the total surface area is not reduced. Moreover, the voids cannot be filled in the end. In the middle and late stages of sintering, the pores are finally eliminated, thus obtaining a fully dense round or curved firebrick.

Buy Circular Fire Bricks from Kerui

- Confirm the specifications, quantity and application scenarios of the refractory bricks you need with Kerui.

- Understand your specific requirements, such as high temperature resistance and chemical corrosion resistance.

- Kerui’s technicians will provide product recommendations and technical support according to your requirements.

- We will provide a detailed quotation. This includes refractories price, transportation costs, delivery time, etc.

- We provide product samples to customers for testing. Ensure that the product performance meets your requirements.

- If you encounter any problems during use, you can contact Kerui’s after-sales service department for help.

There are two major benefits to buying round refractory bricks from Kerui. On the one hand, customers can get high quality refractory bricks. On the other hand, we provide customers with reliable and efficient refractory solutions. In other words, we help customers improve the production efficiency of kilns and reduce maintenance costs.