Corundum Castable

The aggregate and powder of corundum castable are corundum and special grade bauxite clinker. In addition, we add some pure calcium aluminate cement binder and alumina powder. Finally, we will get a refractory castable with an aluminum content of more than 85% and a high-temperature main crystal phase of corundum.

- Al2O3(≥): 80% – 95%

- Bulk Density(≥): 2.7g/cm³ – 3.2g/cm³

- Flexural Strength(≥): 9MPa – 11MPa

- Compressive Strength(≥): 60MPa

What is Corundum Castable?

Kerui’s high-strength corundum castables use fire-proof materials with an Al2O3 content of more than 90% and corundum as the dominant crystal phase. Then, we add appropriate thickeners, coagulants and stainless steel fibers and compound them according to strict secret recipes. Besides, it has the characteristics of good high-temperature compressive strength, wear resistance and erosion resistance, high heat transfer, thermal shock resistance, corrosion resistance, good sealing and rapid setting and early strength. In addition, it has high fire resistance, thermal shock stability, acid and alkali resistance, high strength and no cracks and peeling after burning.

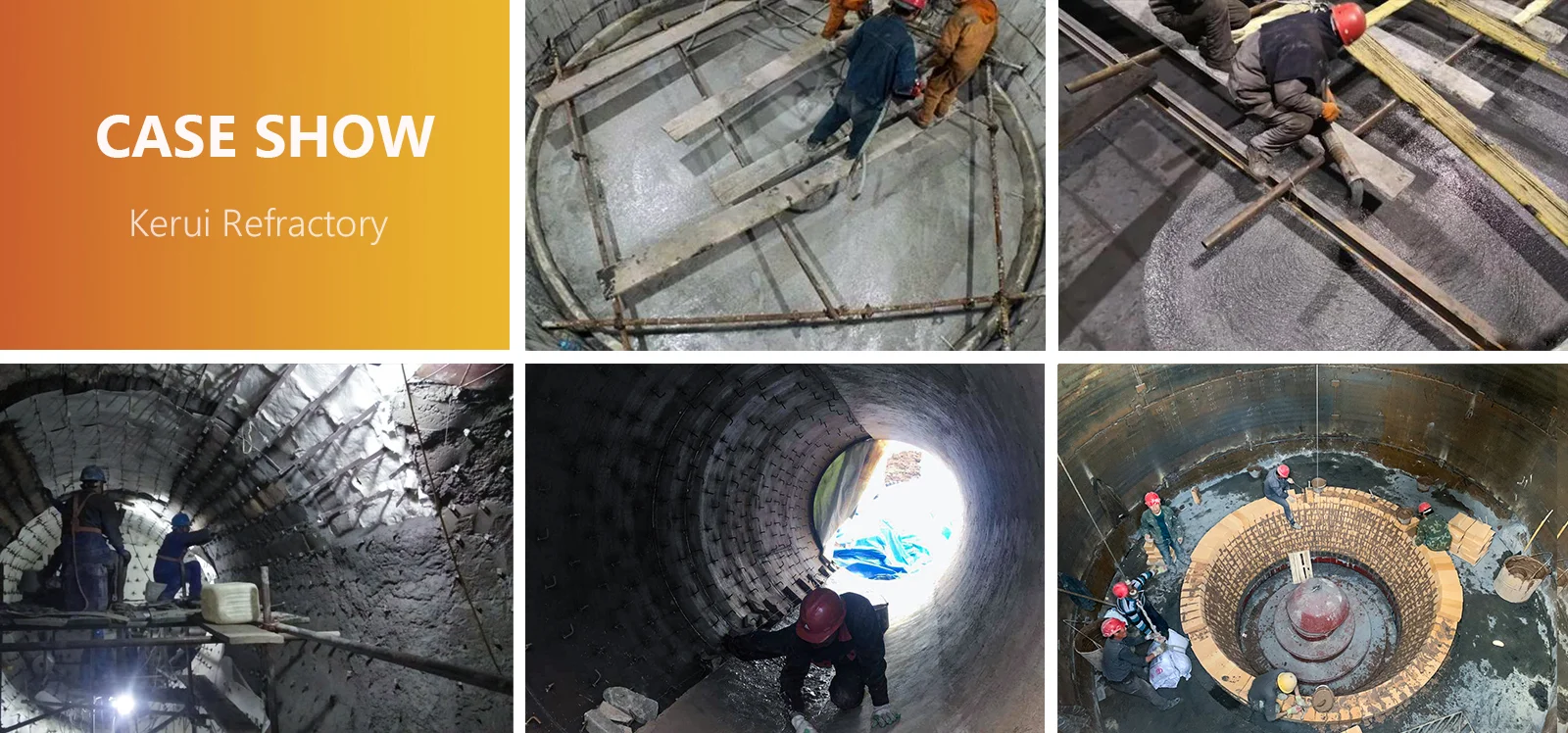

Usually, we use the pouring method for construction. So, customers can either cast it into a complete lining, or they can customize castable prefabricated blocks from the manufacturer and splice them on-site. Moreover, corundum castables have higher mechanical strength and abrasion resistance than high alumina castable and mullite castable.

Physical and Chemical Indicators of Corundum Castable

| Item/Grade | GJ80 | GJ90 | GJ95 |

|---|---|---|---|

| ω (Al2O3) ≥/% | 80 | 90 | 95 |

| Bulk Density ≥/ (g/cm³) | 2.7 | 2.8 | 3.2 |

| Flexural Strength ≥/MPa | 9 | 10 | 11 |

| Compressive Strength ≥/MPa | 60 | 60 | 60 |

| Permanent Linear Change ≤/% | ±0.5 | ±0.5 | ±0.5 |

Advantages of Corundum Castable

Corundum castable for sale has high-energy effects of high-temperature resistance and corrosion resistance. Therefore, it can still maintain stable performance under long-term use. Moreover, we can combine it with silicon carbide, mullite, red stunite, sillimanite, etc. to make composite monolithic castable refractory. Besides, customers can use them in high-temperature furnace lining parts in different atmospheres.

- High strength wear resistance, impact resistance, erosion resistance and oil penetration resistance;

- Good flame retardancy, low water absorption, high and low temperature resistance;

- Great durability and long service life;

- Simple construction, quick operation and easy to master;

- Good integrity, easy to repair, not easy to fall off.

Corundum Castable Uses

We mainly use corundum castables as lining materials for various high-temperature kilns and high-temperature structures. What’s more, you can make it into precast refractory blocks.

- The outer lining of the impregnation tube around the bottom of the ladle and the seat brick and the vacuum degassing device for molten steel;

- Electric stove top caulking, electric stove top triangular area lining;

- Lining bodies for spray metallurgy and argon blown integral spray guns;

- LF furnace cover;

- High-temperature wear-resistant lining for catalytic cracking reactors in the petrochemical industry;

- High temperature wear-resistant lining for circulating fluidized beds and power plant boilers.

Kerui Provides Factory Price of Corundum Castable

Efficient Production Process

Kerui has carefully optimized the production process of corundum castables, improving production efficiency and reducing production costs. So, this allows us to offer corundum castables at relatively low prices, providing customers with an economical option.

Optimized Supply Chain Management

Our company works closely with raw material suppliers and logistics companies. So, through an efficient supply chain network, Kerui is able to obtain raw materials at a lower cost. As a result, Kerui provides customers with lower-priced refractory ramming or castables.

Customer-Centered Service Concept

We provide customized solutions based on our clients’ specific circumstances. Moreover, Kerui’s technical team provides customers with professional advice and technical support. So, we ensure that our customers receive high-quality products within their budget.

Focus on Long-Term Cooperation with Customers

Kerui has won the trust and support of many international customers by providing high-quality refractory products and services. Through long-term cooperation we can achieve mutual benefit and win-win results, helping customers reduce costs and improve production efficiency.

Common Problems and Causes of Corundum Castable

| FAQ | Cause |

| Surface peeling | Firstly, the surface of the template is not smooth; secondly, the release agent is applied unevenly on the surface; thirdly, impurities adhere to the surface. |

| The surface is pitted | Firstly, the material is not stirred evenly; secondly, there are impurities on the surface of the template; thirdly, the air is not discharged cleanly. |

| There are holes or honeycombs in the lining | Firstly, you stirred the castables unevenly; secondly, you vibrated unevenly; thirdly, you pulled out the vibrator too fast. |

| There are small holes in the lining | Firstly, too much water is added during stirring; secondly, there is no slurry on the surface during vibration and the air is not discharged cleanly. |

| The lining has cracks or peeling | Firstly, the curing time is too short; the temperature rises too fast during baking; secondly, the baking temperature is too high. |

| Uneven color | The dry mix of the castable was not evenly mixed before adding water. |

| Sand on the surface of the lining | Firstly, too much water for mixing; secondly, serious slurry running during vibration. |

| Lining body bulge | The mold quality and rigidity are too poor; the mold support is not level. |

| The lining body is out of shape | The mold is not supported properly; the mold is not rigid enough; the mold needs to be removed and replaced and recast. |

| Missing corners and few edges | The lining is demoulded in advance before solidification, lacks strength and is damaged during demoulding. |

| Powdering or white frost on the surface of the lining | No wet straw bag or plastic film was covered during the curing period. Moreover, the water evaporated too quickly, leaving unhydrated fireproof cement remaining, which resulted in peeling or powdering on the surface. |

Conclusion

By choosing Kerui, you can not only get affordable corundum castable but also enjoy professional technical support and high-quality after-sales service. Therefore, whether your project is for a larger enterprise or a small to medium-sized enterprise, Kerui Company is a reliable and competitive choice. Promotions are ongoing, please feel free to contact us or follow us on YouTube to get the best price.