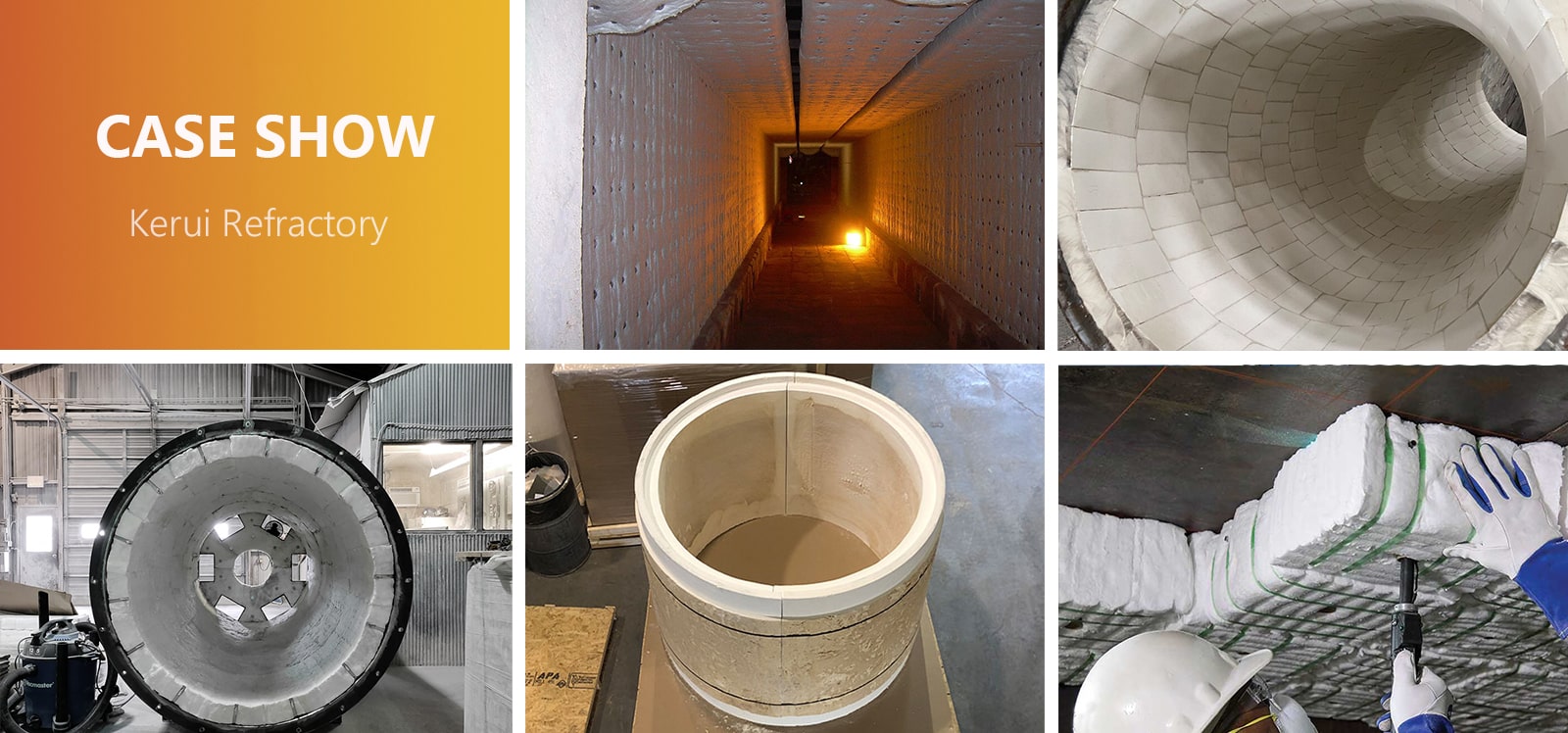

Calcium Silicate Board for Sale

Kerui Refractory high-performance calcium silicate board for sale is a new type of green and environmentally friendly refractory material. Generally speaking, we use it widely in electric power, metallurgy, petrochemicals, environmental protection and other fields.

- SiO2(≥): 46% – 68%

- CaO(≥): 39% – 41%

- Bulk Density: 230g/cm³ – 270g/cm³±10%

- Permanent Liner Change(≤): 2.0%

Introduction of Kerui Calcium Silicate Board for Sale

The main components of calcium silicate cement board are SiO2 and CaO. In addition, Kerui calcium silicate board is a high-quality ceramic fiber product made by molding, autoclaving, curing and other processes. Therefore, Kerui calcium silicate board walls can meet the thermal insulation needs in various high-temperature environments. Moreover, calcium silicate boards are widely used in high temperature industries. Therefore, it is indispensable for high-temperature equipment in industry.

Parameter Details of Calcium Silicate Board for Sale

| Item | Calcium Silicate Insulation Board | |||

|---|---|---|---|---|

| Maximum Use Temperature/℃ | 1000 | |||

| Chemical Composition | ω (SiO2)/% | 46-48 | ||

| ω (CaO)/% | 39-41 | |||

| ω (Al2O3)/% | 0.39-0.42 | |||

| ω (MgO)/% | 0.5-0.7 | |||

| Color | White | |||

| Bulk Density (kg/m³) | 230±10% | 250±10% | 270±10% | |

| Modules of Rupture ≥/MPa | 0.45 | 0.50 | 0.55 | |

| Compressive Strength ≥/MPa | 0.75 | 0.85 | 0.95 | |

| Permanent Linear Change/% | 1000℃*16h ≤ 2.0 | |||

| Thermal Conductivity Coefficient ≤/[W/(m·K)] | 100℃ | 0.065 | 0.067 | 0.072 |

| 200℃ | 0.075 | 0.077 | 0.082 | |

| 400℃ | 0.091 | 0.096 | 0.103 | |

| 600℃ | 0.132 | 0.136 | 0.138 | |

Tips: This table is formulated with reference to China’s refractory industry standards. Contact us for more information.

What are the Advantages of Calcium Silicate Board?

Kerui Cal-Sil board is relatively lightweight and can be customized and installed with simple cutting. This reduces construction time and labor costs. In addition, the Kerui calcium ceramic fiberboard has better flatness, making the installation process easier.

We use it in areas such as industrial equipment insulation and pipe insulation to reduce energy consumption. Therefore, because of the high thermal insulation performance of calcium board, energy consumption and operating costs are reduced.

Our Cal-Sil board is not susceptible to moisture, cracking or corrosion. This allows it to maintain good functionality and appearance in a variety of environmental conditions. So, it extends the service life of the equipment and reduces maintenance costs.

Kerui high-quality calcium silicate board material has high strength and good stability and can withstand certain loads and pressures. Therefore, this makes it a reliable structural material and suitable for use in a variety of industrial applications.

Various Applications of Calcium Silicate Board for Sale

We use calcium silicate sheets widely in various industrial furnaces. For example, steel smelting furnaces, glass kilns, kiln hearths, casting furnaces and aluminum electrolytic cells. Moreover, its high temperature resistance can effectively protect the furnace structure.

Keruigroup calcium silicate panels are used in the power industry for heat preservation and insulation in power stations. Examples include boilers, chimneys and cogeneration units. In addition, its good thermal insulation properties help improve energy efficiency.

We also use calcium silicate plate in quenching furnaces, annealing furnaces and heat treatment furnaces. It can withstand high temperature environments and provide stable heating and cooling conditions. Therefore, it can meet the processing needs of metal materials.

Equipment in the coal gasification, chemical industry and environmental protection industries also require the protection of calcium board. For example, coal gasifiers, petrochemical plants, catalytic cracking plants, flue gas desulfurization plants and flue gas dust collectors.

Benefits of Cooperating with Kerui Refractory

Kerui has extensive experience in production and supply chain management. Therefore, we are able to offer calcium silicate boards at relatively low prices. This enables customers to obtain high-quality products at a more economical cost.

Whether it is size, thickness, density or other technical requirements, Kerui can meet any customized needs of customers. That is to say, this means that we can provide individual solutions that meet the requirements of our customers’ projects.

We are familiar with the needs and standards of the international market. In addition, our ceramic fiber product and other cheap refractory brick are exported to various continents and countries. So, we can guarantee the reliability of transportation.

Kerui has a professional technical team and customer service team. As a result, we are able to respond promptly to our customers’ questions and needs for calcium board. In other words, we can help customers achieve better user experience and satisfaction.

Conclusion

Kerui guarantees the quality of calcium silicate board for sale. Are you still choosing suitable calcium silicate board suppliers? Cooperating with Kerui will be your best choice. In addition, you will get the maximum benefit from Kerui. Welcome to leave a message on the homepage message board or contact us on YouTube.