Refractory Insulation Bricks

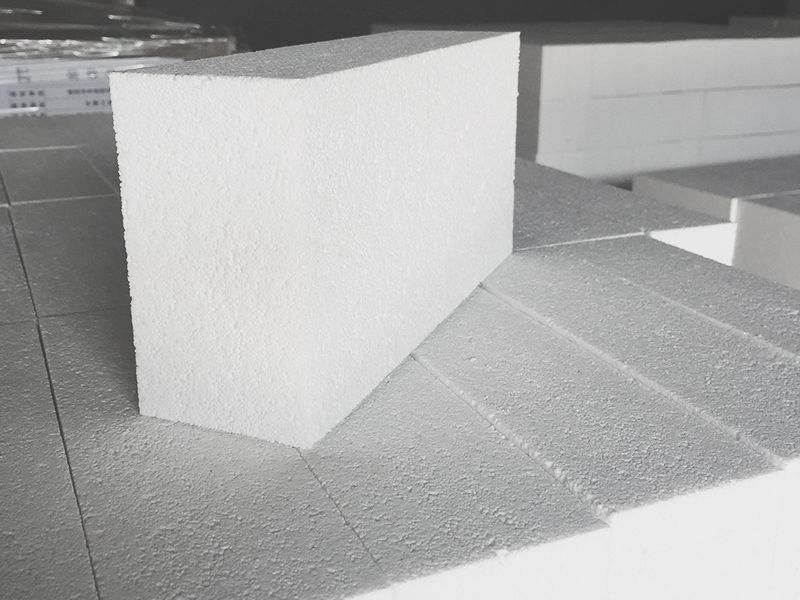

Refractory insulation bricks also known as insulating fire bricks, are specialized building materials designed to provide excellent thermal insulation in high-temperature environments. Kerui refractory insulation brick has excellent performance in high temperature environments.

- Al2O3% (≥): 30 – 99

- Bulk Density (g/cm3): 0.6 – 4.5

- Classification Temperature (℃): 1260 – 1550

- Cold Crushing Strength (Mpa): 1.5 – 4.5

Basic Information of Refractory Insulation Brick

Refractory insulation bricks are essential in high-temperature environments and provide effective thermal insulation. Refractory insulation bricks from Kerui Refractory can withstand temperatures from 1000°C to 1300°C (1832°F to 2372°F) or even higher, based on the specific type and composition. They have a variety of shapes, sizes and densities to suit different applications, such as steel industries, cement industries, glass and petrochemicals industries.

Detailed Composition of Insulation Brick

- Lightweight Aggregates: Refractory insulation bricks mainly consist of lightweight aggregates, such as expanded clay, expanded shale, and perlite. These aggregates are lightweight and have low thermal conductivity, which helps in reducing heat transfer.

- Refractory Clay: Refractory clay is a key ingredient in refractory insulation brick composition. It acts as a binding agent, to hold the aggregates together. In addition, refractory clay has excellent resistance to high temperatures.

- Additives: Various additives are added to the composition to enhance the properties of soft insulating fire brick, which include alumina, silica, or other minerals to enhance the refractory properties of the bricks.

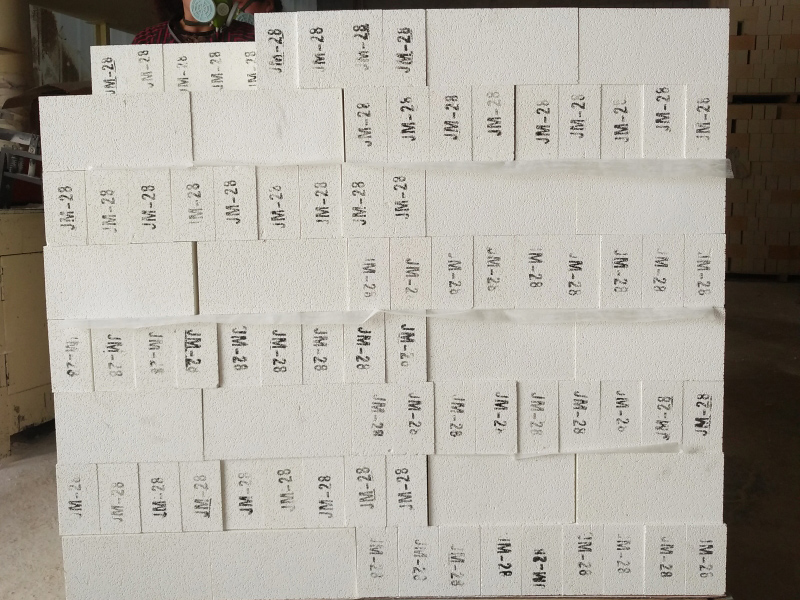

Varied Specifications of Insulating Bricks

Why Refractory Insulating Bricks Have Wide Uses?

The widespread application of refractory insulation bricks is due to their diverse properties. As the insulation refractory, ifb (ifb also called insulation fire brick) has these performances such as lightweight, low thermal conductivity, high heat resistance, excellent thermal insulation and thermal stability, which makes them valuable for applications that require effective heat containment and energy efficiency in high-temperature environments.

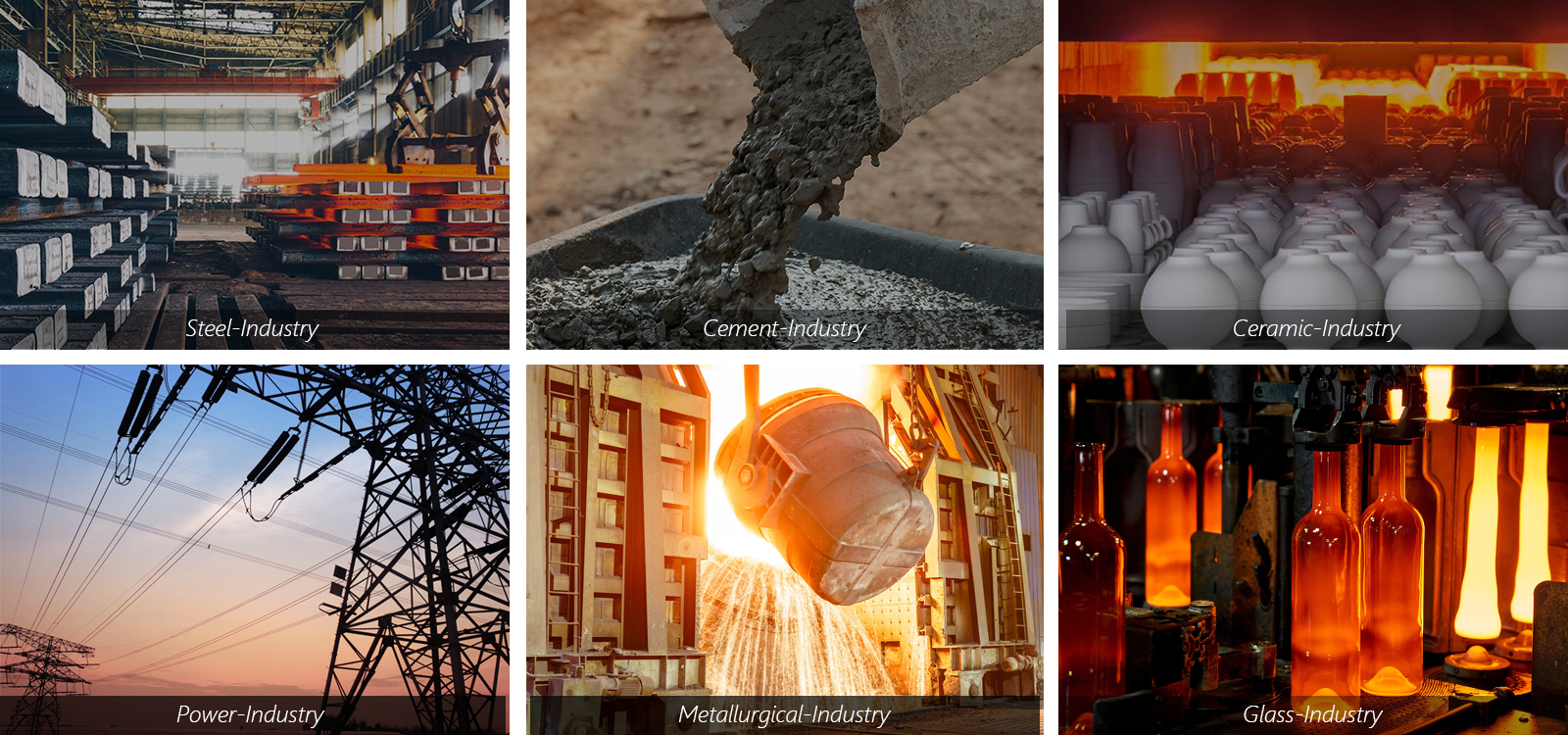

Refractory insulation bricks have wide applications in various industries under high temperature conditions such as the steel industry, cement industry, glass industry, petrochemical industry, ceramic industry, non-ferrous metal industry and power generation industry. Bricks as insulation play a vital role in these industries, to improve energy efficiency and overall operational performance. Contact us so you can know more about the applications of insulation bricks.

Specialized Production Process of Kerui Insulation Bricks

It is an important consideration for buyers about the production processes of refractory manufacturers. Because the production process plays a key role in the quality of insulation bricks. Here are the specialized production process of Kerui refractories,

A Reliable Refractory Insulation Bricks Manufacturer – Kerui

Kerui places a strong emphasis on quality control throughout the production process. For instance, it has strict testing of raw materials, careful monitoring of the manufacturing process, and inspection of the final product. Meanwhile, by quality control, it ensures that the bricks provide consistent reliability.

Kerui refractory bricks manufacturer has a strong supply capability to meet varying customer demands. Thus, with advanced manufacturing facilities and a well-established supply chain, we have the capacity to produce and deliver insulation bricks in large quantities and within specified timelines.

We allow customers to assess the quality, performance, and suitability of the insulation bricks before making a bulk purchase by providing sample testing. Because the option for sample testing helps build customer trust and confidence in the product’s performance.

With rich export experience, Kerui understands international standards and packaging requirements. Therefore, this expertise ensures a smooth and hassle-free export process, to minimize delays and ensure that the insulation bricks reach customers in a timely and secure manner.

What to Consider When You Choose Insulation Bricks?

Assess your project requirements, such as the desired thermal insulation performance, application temperature, and environmental considerations. Besides, understanding your specific needs will help you select insulation bricks that are suitable for your project.

Choosing the cheapest option can compromise quality and performance, which will lead to potential problems and additional costs in the future. Meanwhile, look for reputable insulation bricks suppliers suppliers or manufacturers that offer a good balance of quality and price for insulation blocks.

Evaluate the cost-effectiveness of the refractory bricks. In addition, higher-quality insulation bricks may have a higher cost but can offer better performance, durability, and energy savings over time.

Verify the insulation bricks’ ability to withstand high temperatures. Look for bricks with a high melting point and excellent thermal stability. Besides, consider the maximum temperature the bricks will withstand under these conditions.

If you don’t know how to choose insulation bricks, if you are looking for the right manufacturer of insulation bricks, or if you want to consult the insulation bricks price, contact us to solve your problems! Or you can contact us by Facebook.