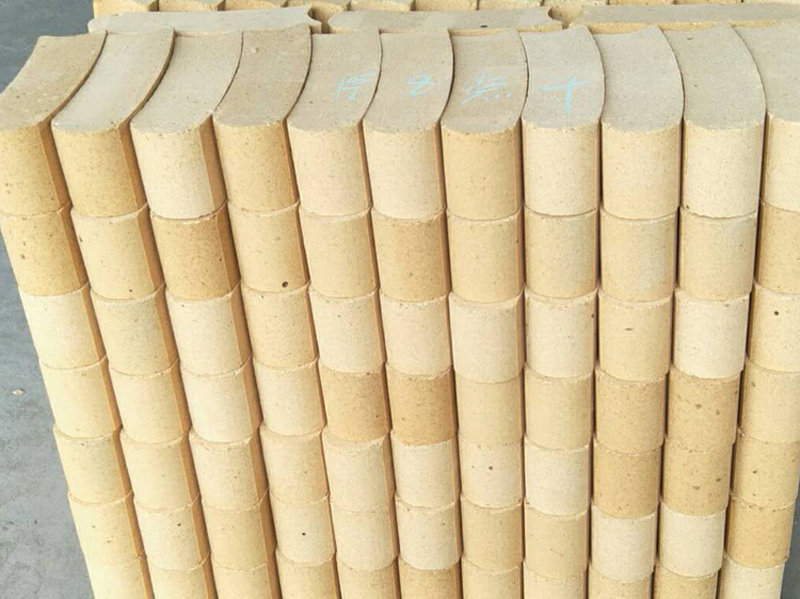

High Alumina Bricks

High alumina bricks are high-quality refractory materials with alumina content typically between 48% and 90%. These refractory bricks can withstand high-temperature environments of different industrial sectors. Kerui Refractory can provide you with the high aluminum bricks you want!

- Al2O3% (≥) :48-80

- Cold Crushing Strength (MPa) :40-60

- Refractoriness Underload (℃) :1420-1530

- Apparent Porosity (%) :19 – 26

What is the High Alumina Brick?

Kerui Refractory high alumina brick is a type of refractory brick, that primarily consists of alumina (Al2O3). Because of the high alumina content in the fire brick, it can enhance thermal insulation, improve resistance to thermal shock, and increase fire refractoriness. Meanwhile, this refractory brick effectively protects the structural integrity of industrial equipment by avoiding heat loss and resisting chemical corrosion.

Specification of High Alumina Refractory Bricks

| Item/Grade | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-55 | LZ-48 | LZ-75G | LZ-65G | LZ-55G | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 80 | 75 | 70 | 65 | 55 | 48 | 75 | 65 | 55 | |

| σ | 1.5 | ||||||||||

| Apparent Porosity/% | μ0 ≤ | 21 (23) | 24 (26) | 24 (26) | 24 (26) | 22 (24) | 22 (24) | 19 | 19 | 19 | |

| σ | 1.5 | ||||||||||

| Cold Crushing Strength/MPa | μ0 ≥ | 70 (60) | 60 (50) | 55 (45) | 50 (40) | 45 (40) | 40 (35) | 65 | 60 | 50 | |

| Xmin | 60 (50) | 50 (40) | 45 (35) | 40 (30) | 35 (30) | 30 (35) | 55 | 50 | 40 | ||

| σ | 15 | ||||||||||

| 0.2MPa Refractoriness Underload/℃ | μ0 ≥ | 1530 | 1520 | 1510 | 1500 | 1450 | 1420 | 1520 | 1500 | 1470 | |

| σ | 13 | ||||||||||

| Permanent Linear Change/% | Xmin Xmax | 1500℃*2h -0.4~0.2 | 1450℃*2h -0.4~0.1 | 1500℃*2h -0.2~0.1 | 1450℃*2h -0.2~0 | ||||||

Composition of High Alumina Fire Bricks

The main raw material used for high alumina fire brick is Bauxite, which is a natural mineral rich in alumina. At the same time, other materials and additives may be included to enhance specific high alumina bricks properties. The general raw material composition of these refractory bricks for sale includes:

Bauxite is the main raw material and source of alumina in high alumina refractory bricks, which typically contains a high percentage of Al2O3 and different amounts of impurities such as SiO2, Fe2O3, and TiO2.

Certain types of clay, such as kaolin clay or fire clay, may be added to the raw material composition of high alumina bricks. Clay helps to plasticize the mixture and improves the processability of the raw material mixture.

As the raw material mixture, sometimes silica (SiO2) can improve the properties of refractory bricks, which can enhance thermal shock resistance and reduce thermal expansion of high alumina bricks.

Binders and the exact high alumina bricks chemical composition can vary based on the manufacturing process and detailed performance requirements of the high alumina bricks. Therefore, careful control of the chemical composition of the fire bricks is crucial to ensure refractory properties, thermal stability, and wear resistance in high-temperature applications.

This refractory brick has more alumina content and better slag resistance, which is suitable for molten metal or other corrosive materials.

These bricks have low thermal conductivity, which helps to minimize heat transfer and improve the overall thermal efficiency of industrial processes.

High Al2O3 content leads to high load-softening temperature. As such, they withstand high temperatures while maintaining structural integrity.

These bricks have a long service life due to their ability to withstand high temperatures. Meanwhile, it reduces the need for frequent maintenance.

These fire bricks have excellent thermal stability. They can maintain mechanical strength even when subjected to rapid temperature changes.

The fire resistance of these bricks is higher than silica bricks. The refractoriness of alumina fire bricks is from 1750°C (3182°F ) to 1790°C (3254 °F).

Advanced Manufacturing Process of Kerui High Alumina Bricks

Wide Applications of High Alumina Brick

Fair Price of Kerui Refractories

Generally, high alumina bricks price is higher than clay fire bricks due to their superior refractory properties. But as a refractory brick manufacturer in China, Kerui Refractory will offer you cheap fire bricks. For accurate and up-to-date pricing information, Contact us now!

Kerui is a manufacturer with more than 20 years of experience in producing high-alumina brick. We have professional technicians who can provide professional project guidance. If you are looking for high alumina brick, you will choose KERUI.