Silicon Carbide Brick

The main raw material of silicon carbide brick is silicon carbide. It has good corrosion resistance and thermal shock stability and is a high-performance refractory material. Therefore, it is an ideal energy-saving material for industrial kilns and is widely used in non-ferrous metal industries and high-temperature furnaces.

- Al2O3% (≥): 20-55

- Apparent Porosity (%): 17-22

- 0.2MPa Refractoriness Underload (℃): 16oo-1700

- Cold Crushing Strength (MPa): 80 – 100

Parameters of Silicon Carbide Brick

Kerui Refractory will customize silicon carbide bricks according to the different needs of customers, so the properties and parameters of sic carbide bricks vary depending on the specific composition, manufacturing processes, and intended applications. Here are some common parameters and properties of sic carbide bricks.

| ltem | Oxide Bond SiC Brick | Green SiC Brick | Corundum Silicon Carbide Brick | Mullite Silicon Carbide Brick | High Alumina SiC Brick |

|---|---|---|---|---|---|

| SiC (% ≥) | 90 | 90 | 70 | 65 | 20 |

| Al2O3 (% ≥) | / | / | / | 20 | 55 |

| Fe2O3 (% ≤) | 0.6 | 0.6 | 1 | 1 | 1.5 |

| Bulk Density (g/cm³ ≥) | 2.6 | 2.6 | 2.7 | 2.3 | 2.5 |

| Apparent Porosity (% ≤) | 17 | 17 | 22 | 20 | 20 |

| Cold Crushing Strength (MPa ≥) | 100 | 100 | 100 | 80 | 80 |

| Refractoriness Under Load (℃≥, 0.2MPa, 0.6%) | 1650 | 1650 | 1700 | 1600 | 1600 |

2 Classifications of Silicon Carbide Brick

Clay Bonded Silicon Carbide Brick

Silicon carbide is the main raw material of clay bonded silicon carbide brick, which is a refractory material fired with clay as a binding agent. Clay bonded silicon carbide bricks have the characteristics of high thermal conductivity, small thermal expansion coefficient, good thermal shock resistance and wear resistance. They are the earliest developed sic carbide bricks among Kerui refractory materials.

SiC itself has a high thermal conductivity, and clay-bonded SiC bricks retain this property. They can efficiently conduct heat, which is advantageous in applications where uniform temperature distribution is critical. In addition, the use of clay as a binder allows for easy forming and shaping of the bricks during manufacturing, making them suitable for customized and complex shapes. Kerui Group can satisfy your different needs for silicon carbide brick types.

Silicon Nitride Bonded Silicon Carbide Brick

Silicon nitride bonded silicon carbide brick primarily consists of sic carbide as the refractory material and sic nitride (Si3N4) as the bonding phase. The proportion of SiC and Si3N4 can vary depending on the specific formulation. So sic nitride bonded sic carbide bricks also are a type of advanced refractory material designed for use in high-temperature and demanding industrial applications. These bricks combine sic carbide grains with a sic nitride (Si3N4) binder to create a refractory material with excellent mechanical and thermal properties.

Silicon nitride bonded silicon carbide brick can withstand extremely high temperatures, typically exceeding 1,400℃. What’s more, These high temperature refractory bricks exhibit exceptional mechanical strength and can withstand mechanical stress, making them resistant to thermal shock and damage due to handling. So they are suitable for use in various high-temperature applications, such as furnaces and kilns.

Performance of Silicon Carbide Brick

Silicon carbide bricks offer exceptional performance in a wide range of high-temperature and demanding industrial applications. Their unique properties make them an ideal choice for environments where traditional refractory materials may not be sufficient. Here are the key performance attributes of silicon carbide refractory.

High Temperature Resistance

SIC carbide bricks can withstand extremely high temperatures, typically exceeding 2,300℃. This makes them ideal for use in applications such as furnaces, kilns, and industrial ovens where conventional refractories would fail.

Thermal Conductivity

SiC has a high thermal conductivity, which allows for efficient heat transfer. This property is advantageous for achieving uniform temperature distribution in high-temperature processes.

Mechanical Strength

silicon carbide refractory exhibit high compressive strength, typically ranging from 200 to 400 MPa. This high strength makes them durable and resistant to mechanical stress and thermal shock.

Dimensional Stability

silicon carbide blocks maintain their shape and size under high-temperature conditions, ensuring that they continue to perform reliably over time without significant deformation or shrinkage.

Corrosion Resistance

These high temperature fire bricks are also highly resistant to corrosion and can be used in chemically aggressive environments, such as in the chemical and petrochemical industries.

Customizability

SiC bricks can be manufactured in various shapes and sizes to suit specific industrial applications, including standard shapes, custom-designed components, and insulation materials.

Longevity

silicon carbide blocks have a long service life, reducing maintenance and replacement costs in high-temperature applications. Their durability and resistance to wear and corrosion contribute to their cost-effectiveness.

Price and Quality Advantages of Kerui Silicon Carbide Brick

Value for Money

Kerui’s production workshop has two 168-meter high-temperature natural gas tunnel kilns. This equipment has fully automatic microcomputer temperature control, the products are fired evenly, and the yield rate is high. In addition, we have source suppliers for our refractory raw materials, so all refractory bricks are sold at ex-factory prices. That is to say, at the same silicon carbide brick price, the quality of Kerui’s silicon carbide bricks is much better than that of other manufacturers. For the same quality, our refractory bricks price will be appropriately lower. Moreover, if you purchase a large quantity of silicon carbide bricks, we will also give you corresponding discounts. We achieve a combination of quality and affordability.

Durability

Kerui has always maintained a rigorous and scientific attitude in producing products. We will strictly control the quality of each brick to ensure that our bricks are durable. Therefore, purchasing Kerui’s sic carbide bricks can reduce your repair time and costs to a great extent.

Performance

we not only have professional production equipment, but also high-quality refractory materials. Therefore, the silicon carbide bricks produced by Kerui have high performance and can fully meet the application requirements in the industrial field.

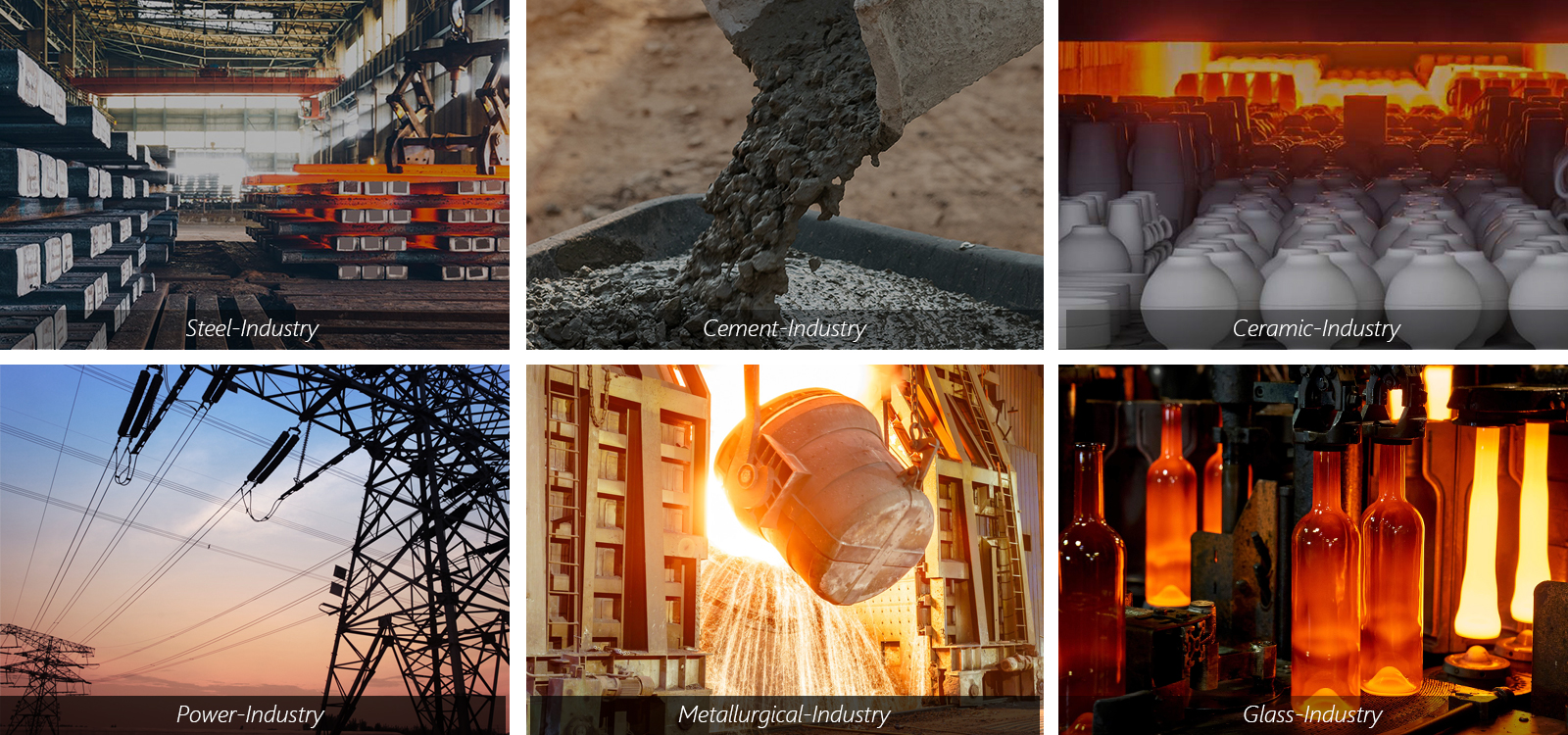

Application Fields of Silicon Carbide Brick

Non-ferrous Metal Industry

SiC bricks in the non-ferrous metal industry play a crucial role in maintaining the integrity and quality of molten metal during processing. They also contribute to the overall efficiency and longevity of equipment and processes in this sector. Their high-temperature resistance, corrosion resistance, and mechanical strength make them indispensable in these applications.

SIC brick is wholesale firebrick, it is applied in the production of non-ferrous metals, such as aluminum, copper, and zinc. Besides, they are used in crucibles, furnaces, and other equipment for melting and processing these metals.

Glass Manufacturing

SiC bricks are used in the construction of glass melting tanks and regenerators, where they can withstand the extreme temperatures and corrosive conditions associated with glass production.

For example, silicon carbide refractory bricks are used to line the interiors of glass-melting furnaces, which are central to the glass manufacturing process. These bricks can withstand the extremely high temperatures required to melt the raw materials, typically exceeding 1,700℃. The excellent thermal conductivity of SiC helps maintain uniform temperature distribution within the furnace.

Steel Industry

In the refractory steel industry, the lining of electric arc furnaces and ladles usually uses sic carbide bricks. Their strong resistance to high temperatures and mechanical pressure allows them to withstand the harsh conditions of steel production.

Ceramics and Refractory Manufacturing

Silicon carbide bricks are used in the production of ceramics and refractories. They can serve as lining materials in kilns and other equipment for firing and processing ceramic products.

Perfect Customer Service of Kerui Refractory

Responsive

Kerui Refractory’s customer service is highly responsive. We ensure the timely resolution of your queries and concerns regarding our sic carbide bricks.

Professionalism

Our business managers at Kerui have an in-depth understanding of the refractory materials we produce and sell. So when you want to buy refractory bricks, whether you want to know about the material or performance of refractory materials, they can answer your questions professionally. And we also provide solutions and refractory technician guidance.

Personalization

We provide personalized service. Our sic carbide bricks are available in different models. We can customize suitable sic carbide bricks according to customers’ specific needs. That is to say, We ensure that customers get the answers they want or solve their problems with minimum effort and time.

Follow-Up

Our customer service does not end with solving a customer’s problem. If you have any questions during the purchase of Kerui’s sic carbide bricks, you can communicate with us. In addition, we also have thoughtful after-sales service. If you don’t know how to install it, we will provide you with technical guidance.

Kerui is a refractory manufacturer. When you buy silicon carbide bricks from us, we will provide you with preferential silicon carbide brick price, professional technical guidance and comprehensive product services. Welcome everyone to inquire on Facebook!