Magnesium Bricks

Are you still looking for affordable and high-quality magnesium bricks? Kerui Refractory can meet your needs. Our magnesium oxide bricks start at US$350 per ton. In addition, the more you purchase, the greater the discounts Kerui will give you.

- MgO (≥):89% – 97.5%

- Bulk Density: 2.85g/cm3 – 3.00g/cm3

- Refractoriness Underload: 1500℃ – 1700℃

- Apparent Porosity: 16% – 20%

Detailed Parameter of Magnesium Bricks

| Item/Grade | M-98 | M-97A | M-97B | M-95A | M-95B | M-91 | M-89 | |

|---|---|---|---|---|---|---|---|---|

| ω (MgO)/% | μ0 ≥ | 97.5 | 97.0 | 96.5 | 95.0 | 94.5 | 91.0 | 89.0 |

| σ | 1.0 | 1.5 | ||||||

| ω (SiO2)/% | μ0 ≤ | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | / | / |

| σ | 0.30 | |||||||

| ω (CaO)/% | μ0 ≤ | / | / | / | 2.00 | 2.00 | 3.00 | 3.00 |

| σ | 0.30 | |||||||

| Apparent Porosity/% | μ0 ≤ | 16 | 16 | 18 | 16 | 18 | 18 | 20 |

| σ | 1.5 | |||||||

| Bulk Density (g/cm³) | μ0 ≥ | 3.00 | 3.00 | 2.95 | 2.90 | 2.85 | ||

| σ | 0.30 | |||||||

| Cold Crushing Strength/MPa | μ0 ≥ | 60 | 60 | 60 | 60 | 50 | ||

| Xmin | 50 | 50 | 50 | 50 | 45 | |||

| σ | 10 | |||||||

| 0.2MPa Refractoriness Underload/℃ | μ0 ≥ | 1700 | 1700 | 1650 | 1560 | 1500 | ||

| σ | 15 | |||||||

| Permanent Linear Change/% | Xmin~Xmax | 1650℃*2h -0.2-0 | 1650℃*2h -0.3-0 | 1600℃*2h -0.5-0 | 1600℃*2h -0.6-0 |

|||

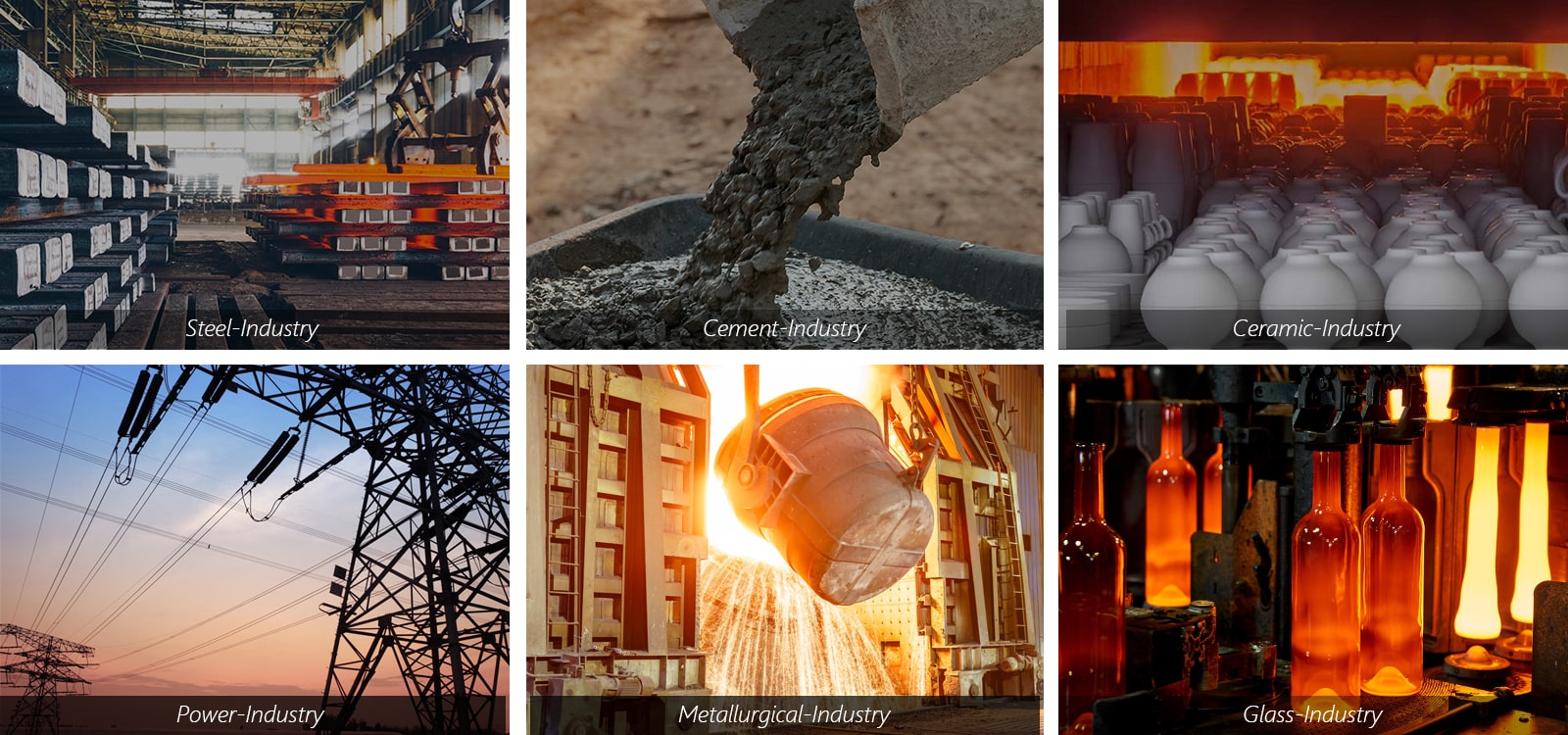

Used in Different Industrial Equipment of Kerui Magnesium Bricks

The application of magnesium bricks in the steel smelting industry is very important. We often use them for the lining of blast furnaces, converters, electric arc furnaces and stirred furnaces. Moreover, magnesite refractory can withstand high temperatures and chemical attacks. It protects equipment structures and improves smelting efficiency.

We also use them extensively in the lining of petroleum cracking furnaces, catalytic cracking furnaces, reformers, hydrogenation units and high temperature reactors. Most importantly, magnesium oxide refractory is resistant to alkali corrosion. Therefore, they are resistant to corrosion from chemicals and high-temperature environments.

The magnesium oxide bricks are widely used in the glass manufacturing industry for lining glass furnaces. Besides, glass furnaces also operate in high temperatures and corrosive environments. Kerui magnesium bricks can provide good thermal conductivity. That is, they guarantee the stability and efficiency of the glass production process.

In the power industry, we use magnesium bricks in boiler and combustion chamber linings, chimneys and flue gas purification equipment. What’s more, Kerui magnesium oxide refractory can withstand the erosion of smoke and provide fire resistance and thermal insulation properties. So, it can ensure the normal operation of power equipment.

Where to Buy Magnesium Bricks?

Offline Manufacturers

You can go to your local manufacturer or visit the website of a reputable manufacturer such as Corey and purchase their products directly. In addition, Keruico’s website (keruico.com) often provides detailed product information, specifications and pricing. Moreover, you can also visit the Kerui factory and inspect its production capabilities. So, we will give you a comprehensive understanding of our products shortly.

Online Marketplace

Online marketplaces such as Alibaba, Amazon and eBay offer a variety of industrial refractory products, including magnesia bricks. Therefore, you can search for magnesium oxide bricks on these platforms and compare prices and reviews from different sellers. Most importantly, always check the seller’s ratings and reviews before you buy. This is the key factor for you to buy high-quality magnesium bricks.

Trade Exhibition

Industry trade exhibitions are an excellent platform to connect with magnesium oxide refractory manufacturers. These events bring together outstanding companies in various industries, such as Kerui. This gives you different options. Besides, you can discuss your needs with experts face-to-face and purchase the products you need directly. Those who are interested can follow us on YouTube for more information.

A Trustworthy Magnesium Bricks Manufacturer – Kerui Refractory

Based on the pursuit of quality, Kerui is committed to providing excellent magnesium oxide refractory bricks. What’s more, Kerui uses high-quality raw materials and strictly controls the production process. Therefore, the quality and performance of each of our magnesia bricks meet high standards. In other words, this ensures the safety and stability of industrial equipment.

Compared with other similar products, Kerui magnesium bricks are favored for their competitive prices. Kerui has effectively reduced product manufacturing costs by optimizing production processes and cost control. Therefore, our magnesia bricks can be provided to customers at a low price of US$350 per ton. In addition, contact us now to purchase more preferential policies.

Customers can choose mgo brick of different sizes, shapes and special requirements according to their project requirements. Kerui professional technical team will work closely with customers to ensure the best adaptability and performance of the product. So, we can ensure that the magnesia bricks we offer fully meet our customers’ expectations and meet their specific needs.

Kerui is committed to providing excellent customer service. Our sales team is always customer-centric, listening to customer needs and providing professional suggestions and solutions. In other words, Kerui provides customers with a full range of services and support in an efficient manner. This includes product consultation, technical support and logistics distribution.

Conclusion

In general, Kerui magnesium bricks have a wide range of applications in industrial equipment. If you want to buy high-quality and affordable magnesia bricks, you can contact us at any time. We will reply to you within 24 hours!