Buy Fire Bricks

There are many ways to buy fire bricks. However, it is a question of where to buy cheap fire bricks. As a reputable entity in the realm of refractory materials, Kerui proudly promises to supply the most cost-effective fire bricks. Therefore, if you want to purchase fire brick, Kerui is the best option.

- Al2O3%% (≥): 55 – 99

- Bulk Density (g/cm3): 1.9 – 3.9

- Refractoriness Underload (℃): 1250 – 1790

- Cold Crushing Strength (MPa): 25 – 200

Do You Know Fire Bricks?

Where to buy or purchase fire bricks? Before buying high density fire bricks, you should know what is fire brick. So do you understand fire bricks? So this part will introduce the bricks to you.

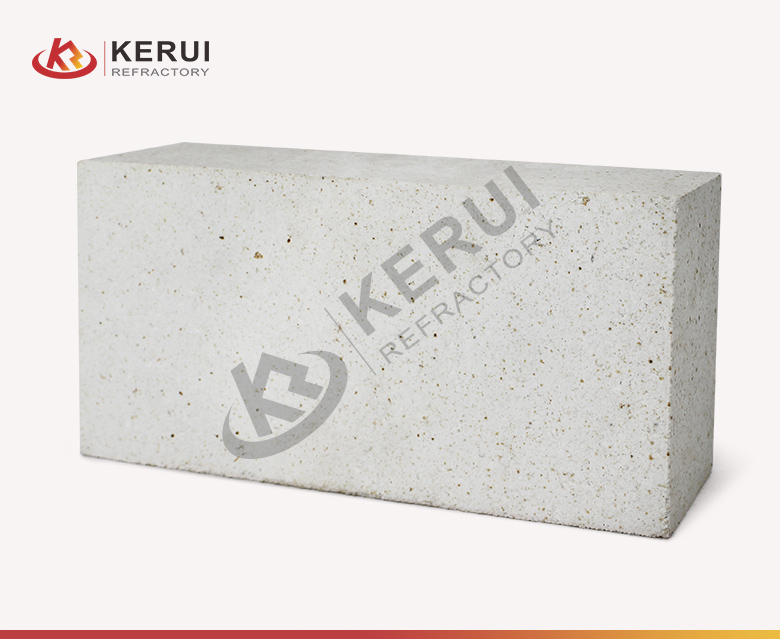

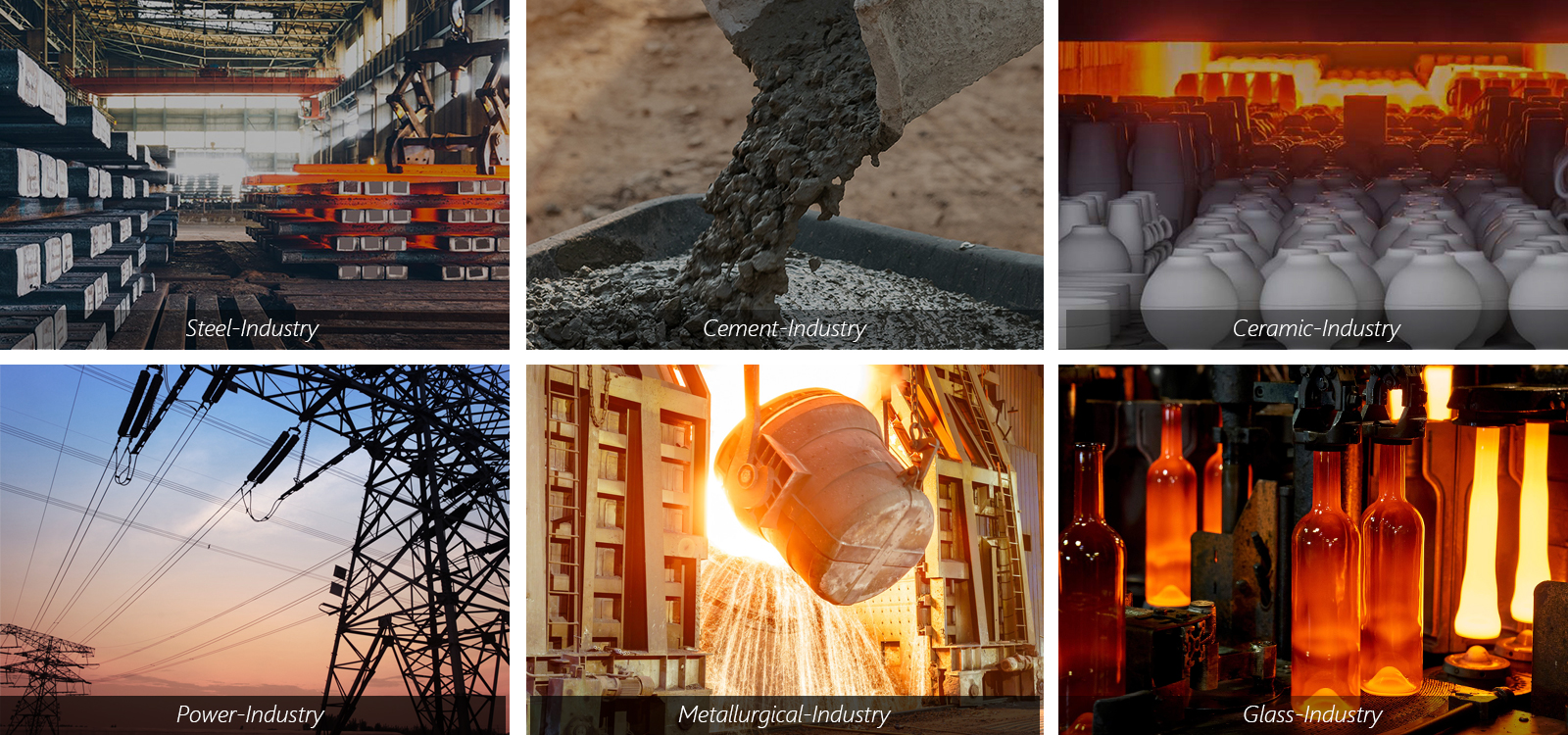

Fire bricks, acknowledged as refractory bricks or heat-resistant bricks, exemplify a specific category of bricks that have the ability to endure elevated temperatures, withstand rigorous mechanical stress and thrive in inhospitable chemical environments. Meanwhile, with good heat resistance, these fire bricks can withstand the temperature of 1580-2000℃ (2876-3632℉). As a result, various industries such as non-ferrous metal industry, steel industry, glass industry, ceramic industry and many other fields can use fire bricks. However, different fire bricks can be suitable for different industries. Additionally, if you want to know which brick is the best option, you can contact us for free.

Fire Brick with Different Types

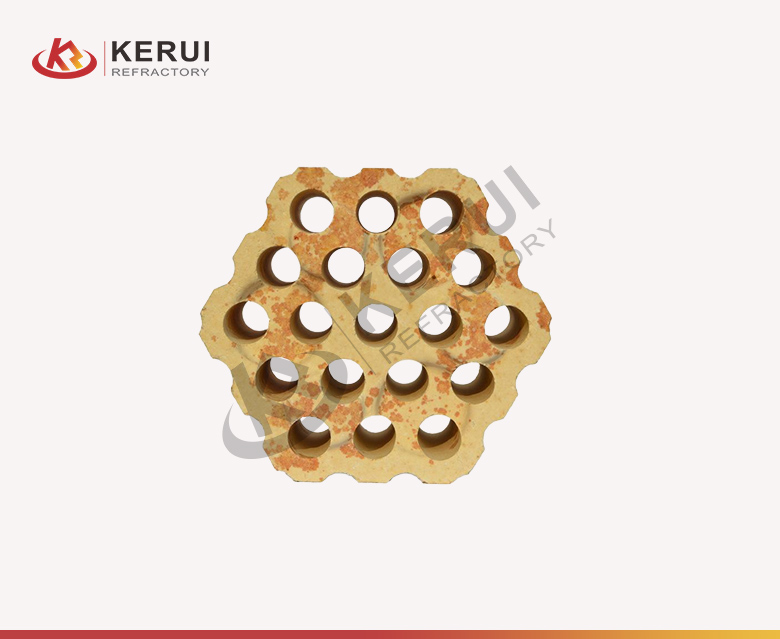

Normally, Kerui divides fire bricks into many types, according to their chemical compositions and dimensions. Here is the basic description of them. They include the best fire bricks element images and colors.

3 Types of Fire Brick

Aluminum-silicon fire bricks primarily comprise Al2O3 and SiO2, which makes them a distinguished series of fire products celebrated for their exceptional refractory properties. Besides, these custom fire bricks boast an impressive refractory temperature that often surpasses 1600℃ (2912℉). So this comprehensive selection ensures that there is an ideal aluminum-silicon fire brick solution available to cater to the specific needs of various industrial applications.

Magnesia refractory bricks, predominantly consisting of magnesia raw material, represent an eminent category of alkaline composite refractory products. Notably, the chemical composition of these new industrial fire bricks primarily comprises MgO and CaO. Meanwhile, the remarkable MgO content typically surpasses 60%. Thus, as high-grade refractory bricks, they boast a diverse range of applications, which underscores their versatility and adaptability in various industrial settings.

SiO2 content in silica fire bricks exceeds 94%. Meanwhile, the bricks primarily consist of high-quality quartz or silica sand. As acid bricks, they are suitable for application in masonry coke ovens. However, it is important to note that silica fire bricks are not suitable for use in thermal equipment operating below 600℃(1112℉) or subject to significant temperature fluctuations. Besides, their limitations in these specific conditions stem from their composition and properties. Nevertheless, within their recommended temperature range, silica fire bricks exhibit remarkable performance and reliability.

SiO2: ≥94%

Fe2O3: ≤1.4%

Apparent Porosity: ≤24%

Cold Crushing Strength: ≥30MPa

Different Dimensions of Fire Brick

Where Do or Can You Buy Fire Bricks?

Where can I buy fire bricks? Generally, most customers will choose to buy firebricks liner through both online and offline channels. In offline channels, you can buy fire bricks in local stores or through industry exhibitions. So you can intuitively feel the quality of the bricks and buy bricks faster. Besides, buying Kerui fire bricks online on Google is a good choice. Because it can give you more options and the most cost-effective bricks.

Additionally, there are too many refractory bricks suppliers on Google. As a result, it is difficult to find a reliable one. Thus, you should consider purchasing from Kerui or other suppliers in many aspects. Besides, you can compare their production qualifications, product pricing, technical expertise, and customer reviews. At the same time, you will find that Kerui Refractory is the best among these refractory bricks suppliers.

Various Properties of Fire Bricks

When you buy fire bricks, their properties are also an important factor to consider. Compared to other manufacturers, the refractory bricks from Kerui Group China have incomparable advantages. Therefore, Kerui fire bricks will ensure the efficiency and longevity of industrial processes.

Widespread Applications of Fire Brick

Kerui fire bricks for sale find widespread application in a multitude of industries and processes. These versatile fire bricks are extensively utilized in furnaces, fireplaces, incinerators, power generation facilities, as well as the refining and petrochemical industries. Besides, they also play a crucial role in smelting and metal processing operations. Due to their ability to withstand high temperatures, Kerui Refractory products rely on controlled high-temperature environments to carry out their operations effectively and reliably. Additionally, if you want to know the specific applications of different refractory bricks, you can contact us at any time.

Kerui Fire Bricks-Best High-temp Solution

Where do you buy fire bricks? Kerui fire bricks always are the most trustworthy. Meanwhile, It will provide all the refractory products you need to extend equipment life. And Kerui is here to serve you at any time. Meanwhile, you can find us on Youtube.