Fire Resistant Bricks for Sale

Kerui fire resistant bricks for sale is a professional refractory material supplier. We are committed to providing our customers with affordable and high-quality refractory bricks. In the field of high-temperature industry, Kerui fire resistance bricks can provide reliable protection for customers’ equipment and processes.

- Al2O3(≥): 55% – 99%

- Bulk Density: 1.9g/cm3 – 3.9g/cm3

- Refractoriness Underload:1250℃ – 1790℃

- Cold Crushing Strength:25MPa – 200MPa

Introduction of Fire Resistant Bricks for Sale

Fire resistant bricks are simply bricks that can withstand combustion and high temperatures. Its refractory degree is around 1700℃(3092℉). Besides, it is usually made of refractory raw materials through batching, molding and sintering. Fire resistance of brick can be made into different fire brick sizes and shapes according to the parts used. In addition, it can also make fire resistant bricks for different purposes according to the raw materials used.

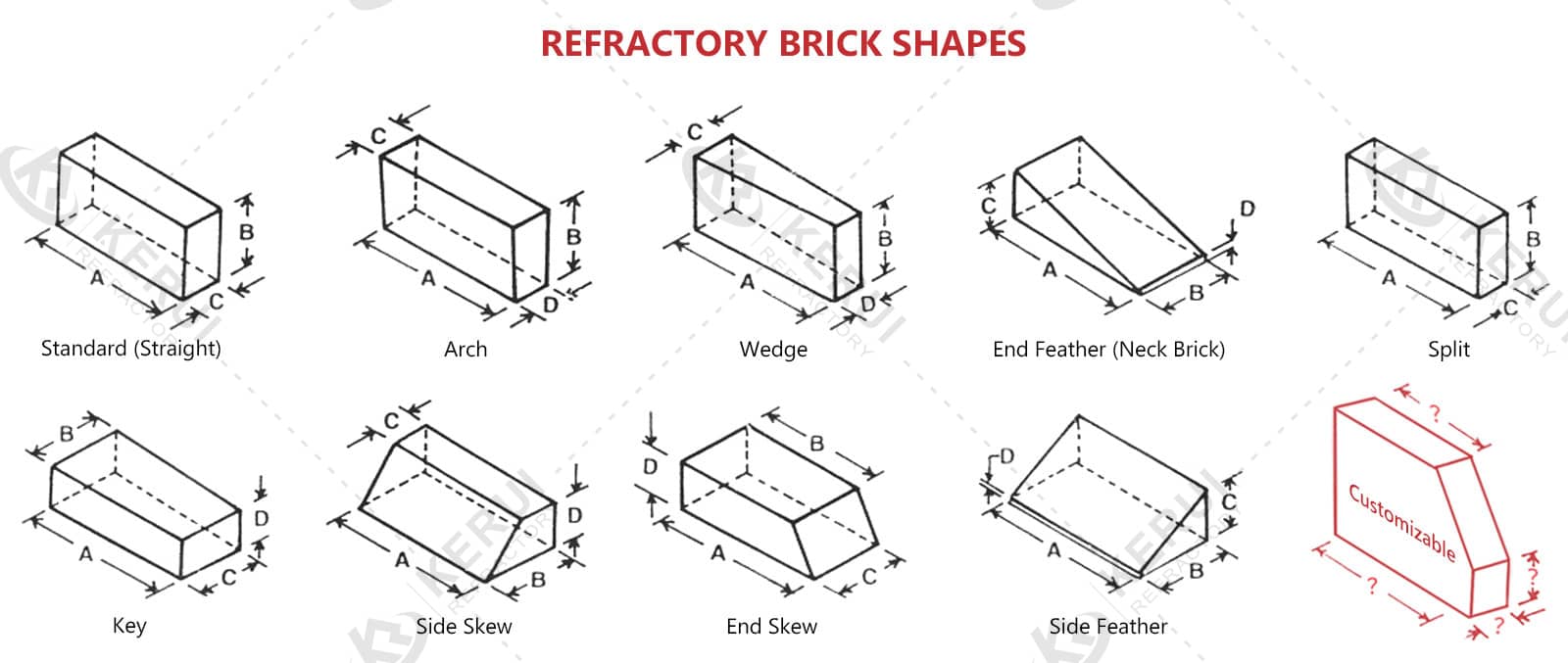

Various Customized Fire Resistant Bricks for Sale of Kerui

Kerui fire resistant bricks for sale are divided into standard sizes and non-standard sizes according to their different sizes and specifications. Standard size fire retardant bricks comply with international or industry standards. Therefore, we commonly use them in conventional high temperature equipment. However, non-standard sizes of fire rated bricks are custom-made to suit special needs. So. they are suitable for equipment with special shape or size requirements.

- Standard fire resistant bricks: the size of Kerui standard fire brick is 230mm×114mm×65mm. Whether you need high alumina fire bricks, silica bricks or magnesia bricks, we can provide them in time.

- Special shaped fire resistant bricks: in addition to standard sizes, Kerui refractory fire brick manufacturer also offers special shapes of refractory fire brick. Such as circular fire bricks, thin refractory bricks, curved fire bricks, anchor bricks and wedge fire bricks.

- Customized fire resistant bricks: customized fire brick is fully customized to the customer’s specific requirements. Besides, Kerui offers size selection, customization of shapes and formulations.

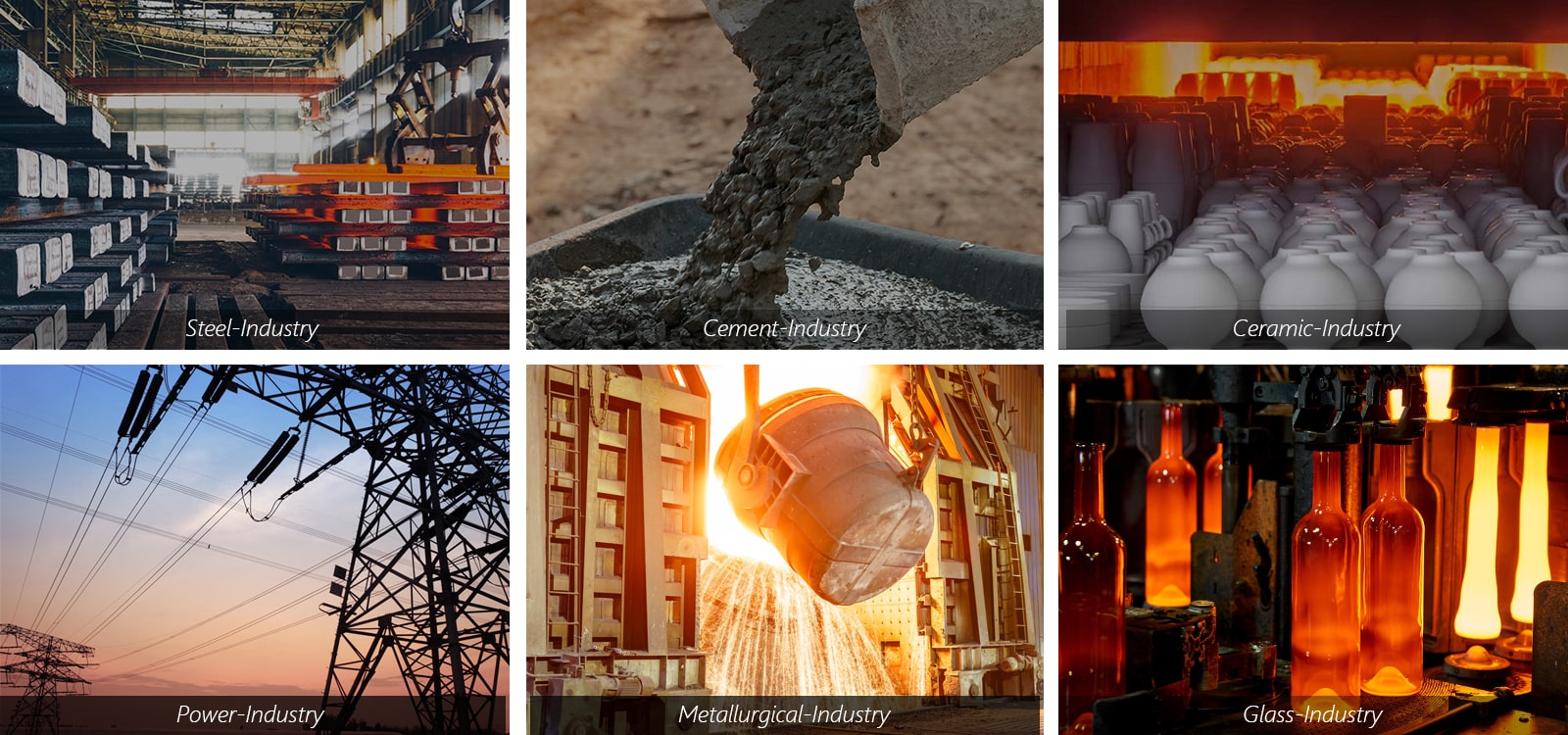

Common Applications of Fire Resistant Bricks for Sale

The fire heat bricks are special materials that are resistant to high temperatures, corrosion and wear. Therefore, we use them widely in various high-temperature industrial equipment. Below are some common industrial equipment. If you want to know more about the application of refractory bricks, please feel free to contact us on YouTube.

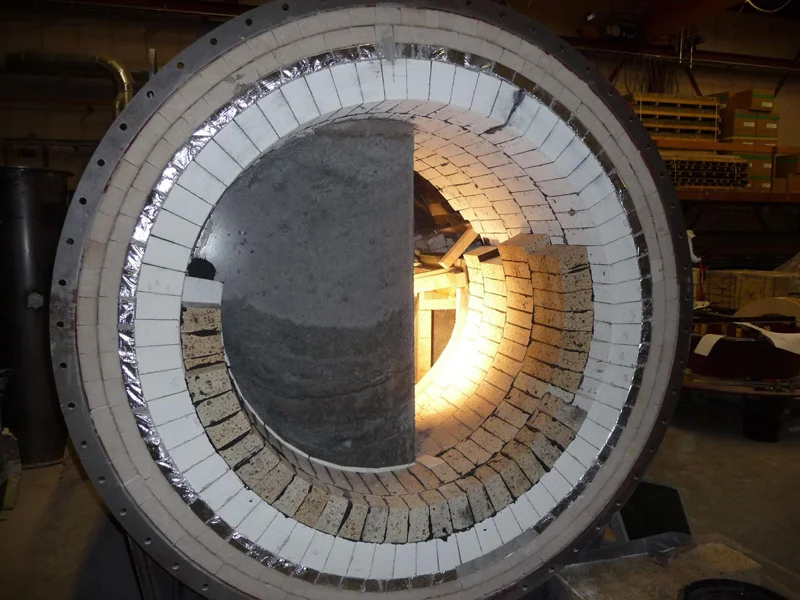

- High-temperature furnaces: blast furnaces, electric arc furnaces and steelmaking furnaces in the metallurgical industry. Kilns and furnaces for glass manufacturing, ceramic manufacturing, petroleum and other industries. They all require the use of refractory bricks to withstand high temperatures and corrosion.

- Heat treatment equipment: heat treatment furnaces, tempering furnaces, quenching furnaces, etc. also often use refractory bricks. We use these devices to control the hardness, strength and other properties of materials during metal processing and manufacturing processes. However, Kerui fire resistant bricks for sale can withstand the demands of high temperatures and thermal cycling.

- Chemical reactor: in the chemical industry, chemical reactors usually require the use of refractory bricks to resist corrosion from chemicals. We use these reactors in various chemical reactions such as petroleum refining, ammonia synthesis, sulfuric acid production, etc.

- Environmental protection equipment: some environmental protection equipment also uses refractory bricks to cope with high temperatures and corrosive environments. For example, incinerators, flue gas desulfurization equipment and waste treatment equipment. These require the use of fire bricks to protect the equipment structure and improve operating efficiency.

- Other industry equipment: we also use high temperature refractory bricks in some other special industrial equipment. Such as railway furnaces, steel rolling mills, aluminum electrolytic cells and glass melting furnaces.

Strong Supply Capacity of Kerui Refractory

Kerui Refractory has stable raw material procurement channels. Moreover, our company has established long-term cooperative relationships with a number of high-quality raw material suppliers. In addition, Kerui uses high-quality refractory raw materials such as high-purity alumina, magnesium oxide and silicon oxide. In other words, this ensures the excellent performance of refractory fire bricks for sale.

We have five factories in Xinmi City, Henan Province, where raw materials are gathered. Moreover, we are equipped with advanced production equipment and technology. That is to say, we are able to meet orders from customers with different sizes of factories and needs. In addition, each factory has independent production lines and strict quality control systems to ensure stable product quality.

Our company implements precise inventory control and management system. By reasonably planning and managing inventory according to market demand and customer orders, Kerui can ensure timely supply. Through scientific inventory management and accurate forecasting, Kerui Refractory Materials can flexibly respond to market demand. Therefore, we can meet our customers’ order requirements.

Kerui Group has established close cooperative relationships with logistics companies to ensure on-time delivery of products and service quality. In addition, Kerui Refractory is constantly optimizing the supply chain process. That is to say, this means that our customers can receive the required fire resistant bricks in time. Besides, we also provide professional technical support and after-sales service.

Conclusion

When choosing a refractory fire resistant bricks for sale supplier, choose Kerui Refractory and you will get professional services and refractory material solutions. Moreover, Kerui also provides customers with high-quality fire resistance bricks that meet their specific sizes and needs. Feel free to contact us for a free quote!