Refractory Fire Bricks for Sale

Refractory fire bricks for sale are important materials used in high temperature environments. It is widely used in the lining of furnaces, kilns and other high temperature resistant equipment. When used in construction kilns and various thermal equipment, it is crucial to choose high-quality refractory fire bricks.

- Al2O3% (≥): 55-82

- Bulk Density (g/cm³): 1.9-3.9

- Refractoriness Under Load (℃): 1250-1790

- Cold Crushing Strength (MPa): 30-200

Introduction to Refractory Fire Bricks for Sale

Refractory fire bricks are simply bricks that can withstand combustion and high temperatures. What’s more, their refractory resistance is generally around 1700°C. We usually made them by batching, shaping and roasting refractory raw materials.

Refractory fire bricks are specialized building materials designed to withstand high temperatures, corrosive environments and mechanical wear. Besides, these bricks are crucial components in various industries, providing essential thermal insulation and structural stability in applications such as furnaces, kilns, incinerators and other high-temperature environments.

Properties of Refractory Fire Bricks for Sale

Refractory fire bricks are a special building material with excellent physical and chemical properties. Therefore, this allows it to remain stable in high temperatures and harsh environments. The following are common physical and chemical properties of high temperature fire bricks.

Physical Properties of Refractory Fire Bricks

The high temperature resistance of refractory fire bricks allows them to maintain structural stability and integrity under extreme heat. Generally speaking, refractory bricks can withstand high temperatures of 1,700 ℃. This makes them ideal materials for high-temperature equipment such as furnaces, kilns and furnaces.

Excellent refractory fire bricks generally have a low thermal conductivity coefficient, which means they reduce the transfer and loss of heat. This is crucial for the insulation of high-temperature equipment. By reducing heat loss, refractory bricks can improve energy efficiency and ensure stable operation of equipment.

Typically, the best fire bricks have low water absorption. This is because their materials have higher density and lower porosity. Low water absorption makes refractory fire bricks less susceptible to moisture and cracking in high-temperature environments, so they can maintain structural stability.

The density of refractory fire bricks refers to their mass per unit volume. In fact, refractory bricks have a higher density. This allows them to withstand mechanical stress and pressure and provide sufficient strength and durability. In addition, higher density also helps improve thermal insulation performance.

Chemical Properties of Refractory Fire Bricks

Excellent corrosion resistance means that refractory fire bricks can resist the erosion of corrosive gases, liquids and solids. This maintains the stability of the structure. This therefore makes refractory bricks an ideal material in chemical, metallurgical and other corrosive environments.

In some industrial applications, refractory fire bricks often need to withstand the impact and friction of materials. Therefore its wear resistance is very important. Good wear resistance can extend the service life of refractory bricks and reduce the frequency of maintenance and replacement.

Lower apparent porosity means the refractory brick is denser and has a lower percentage of voids or pores. For example, high alumina bricks. This improves the thermal insulation and vibration resistance of the refractory fire bricks. That is to say, this reduces heat conduction and vibration transfer.

During some industrial production processes, equipment may be subject to shock and vibration. This poses a challenge to the stability of refractory bricks. Refractory fire bricks with good vibration resistance are able to maintain integrity and performance under these harsh conditions.

Molten slag is a molten substance formed at high temperatures. There is a certain threat to the durability of refractory fire bricks. Refractory bricks with excellent slag resistance can prevent slag from infiltrating into the structure. Therefore meet the stable production of industry.

Just like ceramic fiber products, the high mechanical strength of refractory fire bricks means that it is highly resistant to mechanical stress and pressure. In other words, High mechanical strength helps refractory fire bricks resist external pressure and impact, ensuring their long-term stable performance.

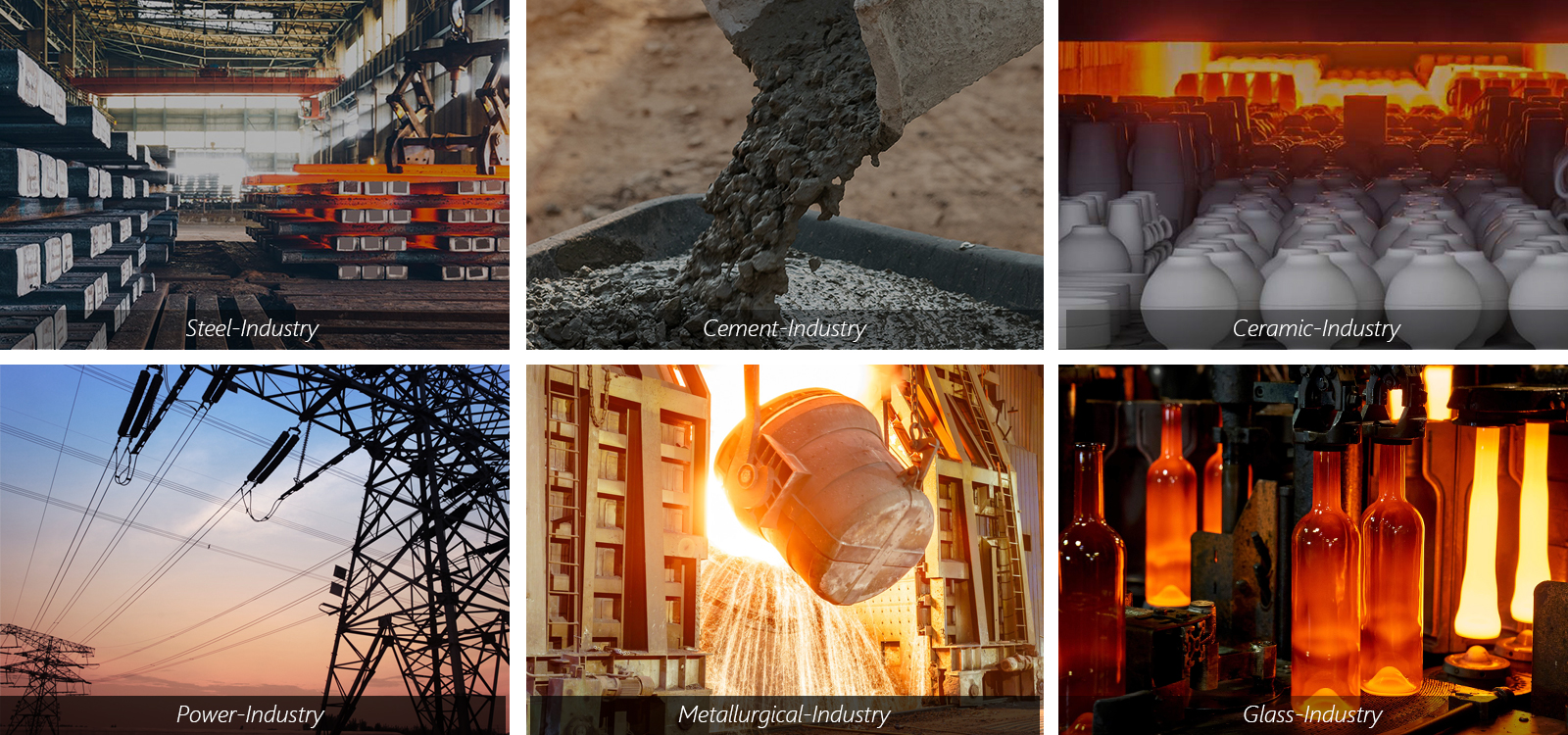

Application Industry of Refractory Fire Bricks for Sale

Steel Industry

Refractory fire bricks are widely used in the steel industry. We use them as the lining and protective layer of high-temperature smelting equipment. Such as blast furnaces, converters, electric furnaces, hot blast furnaces and steelmaking furnaces. Refractory fire bricks can withstand the smelting process at high temperatures and the erosion of corrosive melts, protecting equipment from damage.

Glass Industry

In the glass manufacturing process, refractory fire bricks are widely used in the lining and insulation of glass furnaces. The high-temperature glass liquid and chemical corrosive substances in the glass furnace place extremely high requirements on materials. Fortunately, refractory fire bricks are able to withstand these extreme conditions, ensuring the structural stability and efficient operation of the kiln.

Ceramic Industry

The refractory fire bricks are mainly used in kilns and sintering equipment in the ceramic industry. Ceramic kilns need to withstand high temperatures and chemically corrosive environments. Refractory fire bricks are able to remain stable under these harsh conditions. In addition, the low apparent porosity of refractory fire bricks helps improve the quality and surface finish of ceramic products.

Chemical Industry

Refractory fire bricks have good corrosion resistance and chemical stability. Therefore, it is widely used in the lining and protective layer of chemical reactors, furnaces, pipelines in the chemical industry. Besides, we can use refractory fire bricks with refractory cement. they resist the erosion of corrosive media such as acids, alkalis and salts. That is to say, this ensures safe operation and long service life of the equipment.

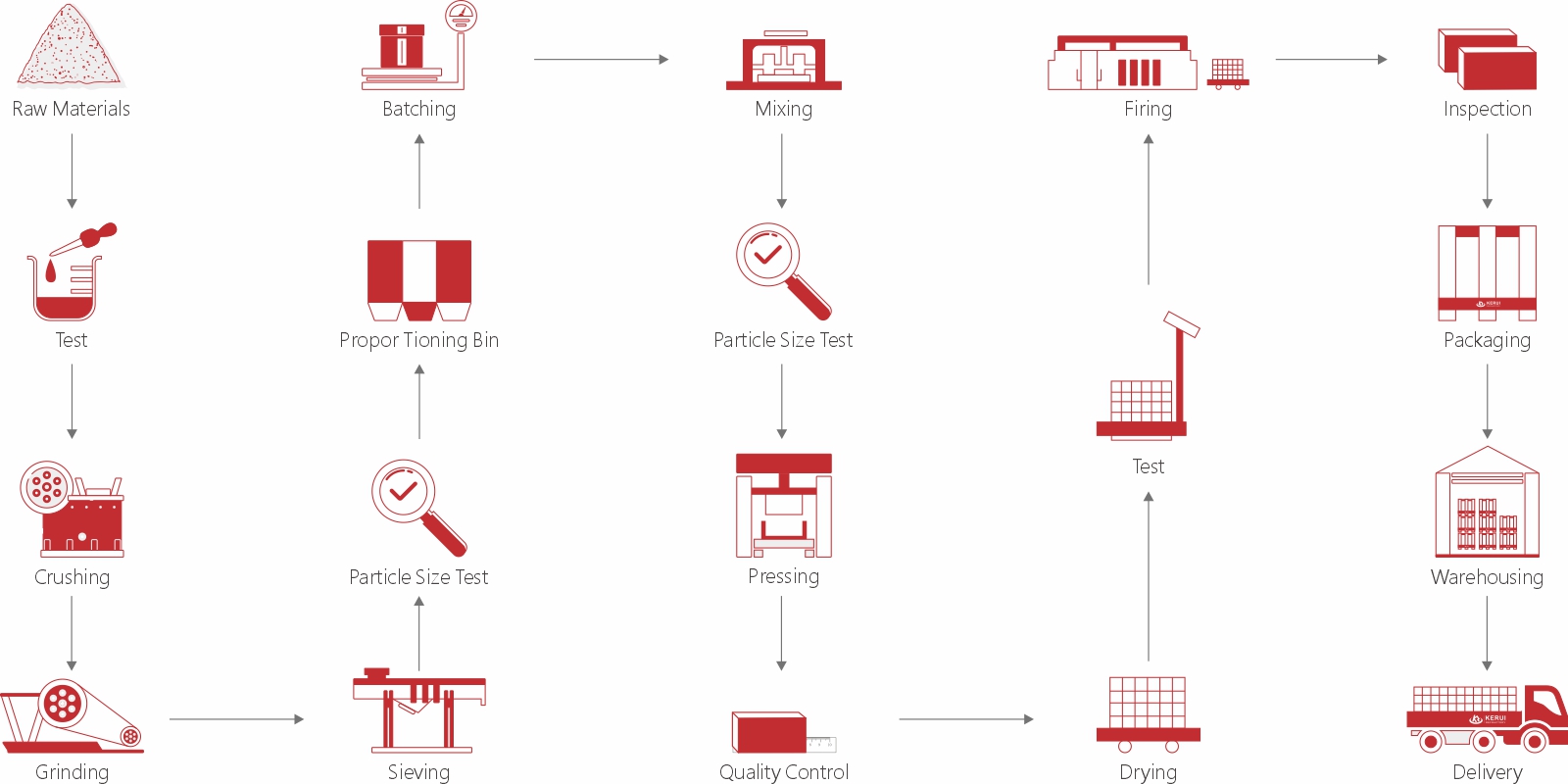

Manufacturing Process of Refractory Fire Bricks for Sale

Raw Material Preparation

The first step is to prepare the raw materials required for the production of refractory fire bricks. The main raw materials include high-alumina, silica, clay and various additives. In addition, we carefully select, crush and mix these materials in the appropriate proportions. It can ensure consistent quality and desired properties in the final product.

Mixing and Shaping

The prepared raw materials are mixed thoroughly to achieve a homogenous blend. Then, water or other binders may be added to enhance the plasticity of the mixture. The mixture is then shaped into bricks using various methods such as molding, extrusion, or pressing. The bricks can be formed into different shapes and sizes depending on the specific requirements.

Drying

After forming, the bricks go through a drying process to remove moisture. We usually do them by machine drying in a drying chamber. The purpose of drying is to eliminate moisture in the bricks and improve the strength and dimensional stability of the bricks. In addition, brick insulation also has this production process.

Sintering

The dried bricks are sintered in kilns at high temperatures to undergo a sintering process. The sintering temperature varies depending on the type of refractory fire bricks being produced. During firing, the raw materials undergo chemical and physical transformations, resulting in the formation of a dense and stable structure. This process ensures the bricks attain their desired refractory properties.

Cooling and Quality Control

After the firing process, we gradually cooled down the bricks in the kilns. This controlled cooling helps to prevent thermal stresses and cracking. Once cooled, the bricks undergo rigorous quality control checks. These checks may include dimension measurement and testing of properties such as compressive strength, thermal conductivity and chemical resistance.

Packaging

The final step involves sorting the bricks based on refractory fire bricks’ specifications and quality. We meet the required standards package of the bricks for sale and transportation. Proper packaging ensures the protection of the bricks during storage and transit.

Kerui Sells High Quality Refractory Fire Bricks

Rich Export Experience

Kerui refractory bricks supplier has more than twenty years of export experience. What’s more, we have established solid cooperative relationships with customers in many countries and regions around the world. We have an in-depth understanding of the needs and standards of international markets. In addition, our export experience enables us to provide professional services to our customers, ensuring maximum customer satisfaction.

Excellent Quality

Kerui always has high requirements for product quality and performance. We use high-quality raw materials, combined with advanced production technology and strict quality control processes. This ensures that each refractory brick is of exceptional quality and performance. So, these advantages enable our refractory bricks to perform outstandingly in the harsh environments of various high-temperature industries.

Diverse Refractory Fire Bricks

As refractory fire brick suppliers, Kerui provides a diverse range of refractory brick products to meet the different needs of customers. Kerui offers refractory bricks in different materials, shapes and specifications. For example, high-performance magnesia bricks, clay bricks and high alumina bricks. Customers can choose the most suitable refractory bricks according to specific application scenarios. This ensures optimal performance and results.

Applicable to Various Industries

Whether it is in the steel, glass, ceramics, or chemical industry, we can provide customers with suitable refractory brick solutions. Kerui refractory bricks can withstand harsh environments such as high temperature smelting and chemical corrosion. And the mechanical impact is also very strong. This protects the device to a great extent and extends its service life. Choosing Kerui is equivalent to choosing peace of mind.

Why Choose Kerui Refractory Fire Bricks for Sale

Kerui Group has a high-quality technical team with rich industry experience and professional knowledge. Our experts will communicate directly with you and provide all-round technical cooperation. We will provide customized technical support for purchasing refractory bricks based on your needs to ensure you get the best solution. Our goal is to help you optimize your production processes, increase efficiency and reduce costs.

Kerui is known for its stable refractory supplies. Kerui has its own five major production plants with strong production capacity. In addition, we also adopt advanced logistics management systems to ensure timely delivery of products. Whether your order is large or small, we can meet your needs. Our efficient supply chain management allows us to respond flexibly to fluctuations in market demand, which ensures your production schedule is not disrupted.

Always putting the needs of customers first is what Kerui has always done. Ensure maximum customer satisfaction through timely response, effective communication and pre-sales and after-sales services. In other words, our business managers will establish close communication with you, understand your purchasing needs and provide you with effective support. What’s more, our goal is to exceed your expectations and achieve success with you.

In order to provide customers with competitive prices, Kerui Refractory focuses on comprehensive control of the cost of refractory bricks. We achieve product economy by continuously optimizing production processes, improving efficiency and reducing operating costs. We also provide flexible pricing strategies and there will be corresponding discounts for large purchases. So we will meet the budget and needs of different customers.

The Importance of Choosing High Quality Refractory Fire Bricks for Sale

Safety

High quality refractory fire bricks can withstand extremely high temperatures and pressures in high-temperature environments. This can effectively protect equipment and personnel safety. In addition, they have excellent fire resistance and can withstand chemical corrosion and mechanical impact. What’s more, choosing high quality refractory fire bricks can reduce the risk of fires and accidents and ensure the safety and stability of the production environment.

Sustainability

High quality refractory fire bricks of Kerui Group China are usually made of high quality raw materials and processed with fine craftsmanship. They have a long service life and stable performance, reducing replacement frequency and resource consumption. By choosing high-quality refractory bricks, you can reduce the need for raw materials and reduce waste generation. Besides, it also has a smaller impact on the environment and meets the requirements of sustainable development.

Save Energy

Wonderful refractory fire bricks have excellent thermal insulation properties and can effectively reduce heat loss. Therefore, they can maintain stable temperatures in high temperature environments and reduce energy consumption. That is to say, by choosing high quality refractory fire bricks as insulation materials, we can reduce energy consumption and improve energy efficiency. Thereby achieving the goal of saving energy.

Save Maintenance Costs

Kerui great refractory fire bricks have high durability and corrosion resistance, reducing the frequency of equipment damage and repairs. They maintain stable performance over time and are not susceptible to damage from high temperatures, chemicals and mechanical shock. Choosing excellent refractory bricks can reduce repair and replacement costs, reduce production interruption time and improve production efficiency and economic benefits.

Conclusion

As refractory fire brick manufacturers, Kerui commits to providing high-quality refractory brick solutions to customers around the world. So we can meet the needs of different industries for high-performance materials. When you choose our company, you will receive all-round support. Finally, welcome to contact us on Pinterest, we look forward to establishing a long-term partnership with you.