What is the difference between refractory ramming mass and refractory castables? First of all, both products are unshaped refractory materials. Ramming mass is constructed by ramming and hardened by heating. Castables are constructed by pouring and can harden without heating. We make refractory castables and ramming mass from various aggregates, powders and binders in reasonable proportions, which are all unshaped refractory materials. Therefore, although they are the same type of amorphous refractory materials, they have many differences.

The Difference in Raw Material Ingredients

We use aggregates and powders of a certain particle size, plus binders and additives to make ramming mass. We use the mechanical ramming construction method. Ramming mass includes corundum ramming mass, high alumina ramming mass, silicon carbide ramming mass, AZS ramming mass, silica ramming mass and magnesium ramming mass.

Refractory castable is a granular and powdery material made of refractory materials and a certain amount of binder. It has high fluidity, so we mold it by pouring. The three major components of castables are main components, additional components and impurities. They are aggregates, powders and binders. In addition, refractory castables include high-aluminum castables, wear-resistant castables, plastic refractory castables, silicon carbide castables, etc.

Differences in Scope of Construction Application

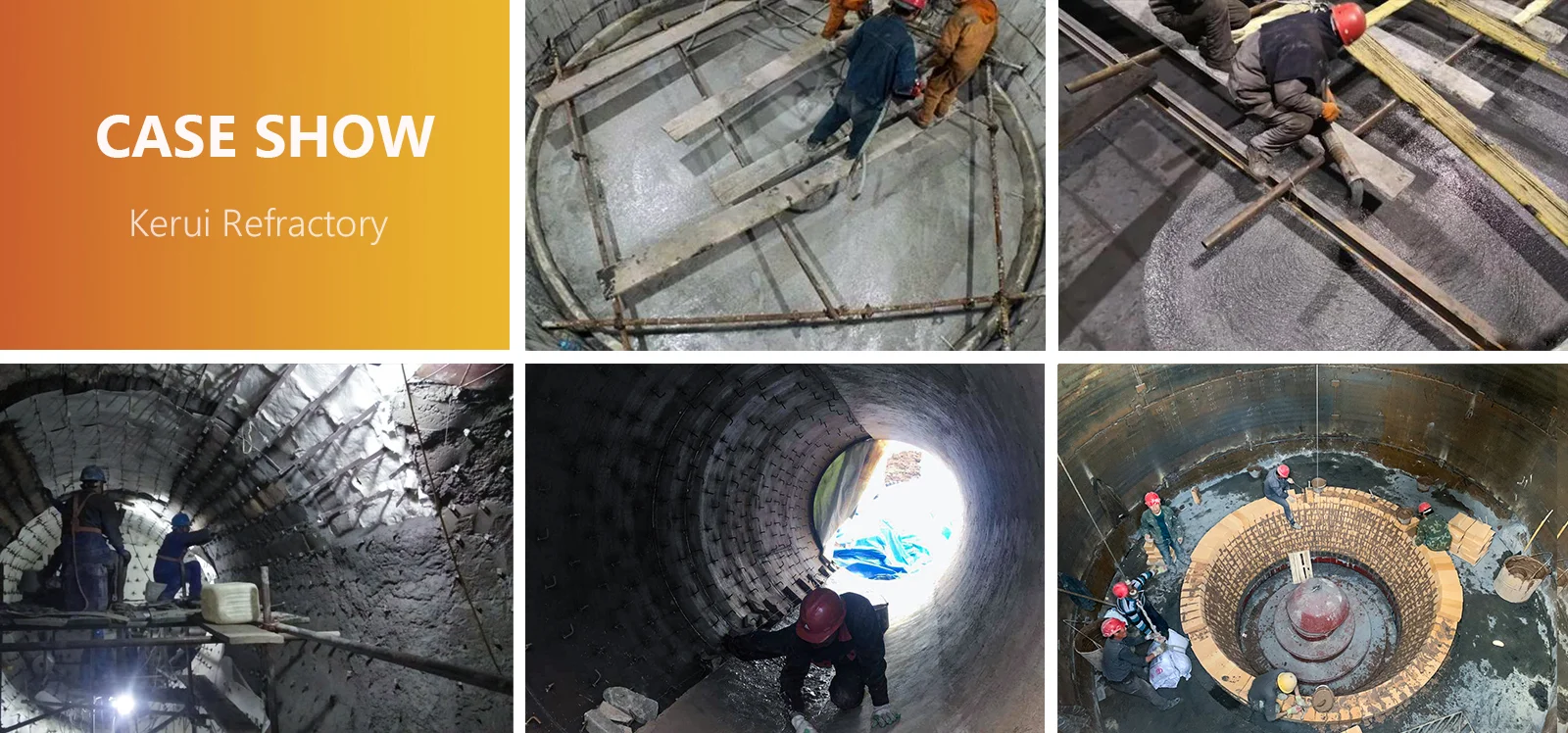

When we are ramming the ramming material, we must pay attention to the uniform force and smooth construction. In areas of the kiln where you cannot lay refractory bricks or where brick laying is difficult, you can use ramming mass. The construction of ramming mass is relatively simple. We often use it to fill the gap between furnace cooling equipment and masonry or as filler for the masonry leveling layer.

We mainly use refractory castables to construct various heating furnace linings and other integral structures. In other words, we can use refractory castables for pouring and molding key parts of the furnace body. For example, near the furnace door frame and feeding port. Moreover, we generally use castables to cast the molten metal pouring runner. Additionally, we can use it in areas that require regular touch-ups.

Conclusion

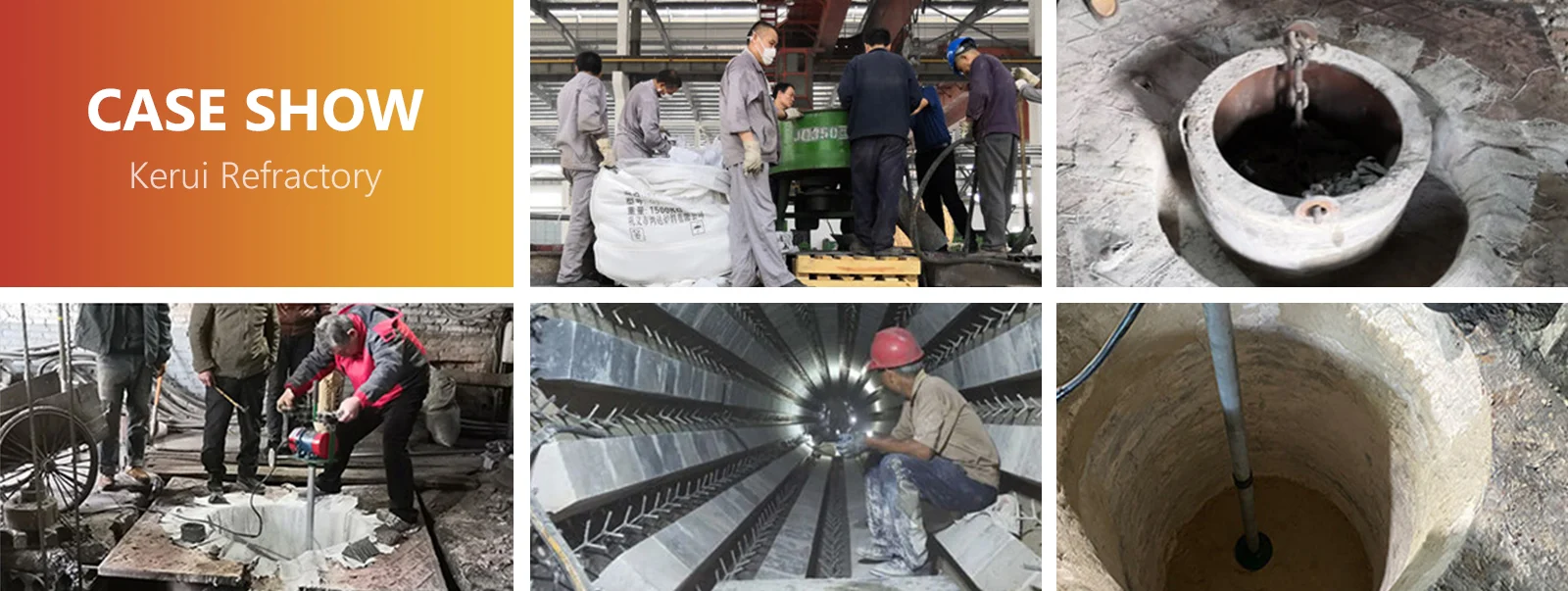

When selecting refractory materials, you need to consider which type of ramming mass or refractory castables to use based on the size, requirements and specific circumstances of the construction project. In addition, you can also contact Kerui to get free technical solutions.