Corundum Bricks

Corundum bricks are refractory materials with alumina content (Al2O3) over 90%, which have thermal stability and can withstand extremely high temperatures. Customers often use corundum bricks for key parts of furnaces. Kerui’s corundum bricks are important refractory materials in high-temperature industrial environments.

- Al2O3% (≥): 95 – 99

- Bulk Density (g/cm3):3.1 – 3.2

- Refractoriness Underload (℃): 1700

- Apparent Porosity (%): 19 – 20

What Are Corundum Bricks?

Corundum bricks for sale consist of corundum that has high refractoriness with a high melting point. The load softening temperature of corundum refractory bricks is 1700℃ (3092℉). Meanwhile, They are known for their exceptional strength, resistance to high temperatures, and excellent chemical stability. Thus, industries often use them in furnace linings, incinerators, and other high-temperature equipment.

Specification of Kerui Corundum Bricks

| Item/Grade | GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 | ||

|---|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 99.0 | 99.0 | 98.0 | 95.0 | |

| ở | 0.30 | |||||

| ω (SiO2)/% | μ0 ≤ | 0.15 | 0.2 | 0.5 | / | |

| ở | 0.08 | |||||

| ω (Fe2O3)/% | μ0 ≤ | 0.10 | 0.15 | 0.2 | 0.3 | |

| ở | 0.03 | |||||

| Apparent Porosity/% | μ0 ≤ | 19 | 19 | 19 | 20 | |

| ở | 1 | |||||

| Bulk Density (g/cm³) | μ0 ≤ | 3.20 | 3.15 | 3.15 | 3.1 | |

| ở | 0.05 | |||||

| Cold Crushing Strength/MPa | μ0 ≥ | 80 | 80 | 80 | 100 | |

| ở | 15 | |||||

| Permanent Linear Change (1600℃*3h)/% | Xmin Xmax | -0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 | |

| 0.2MPa 0.6% Refractoriness Underload/℃ | Xmin | 1700 | 1700 | 1700 | 1700 | |

Classification of Kerui Corundum Bricks

According to the Production Process

They are refractory materials that are produced by sintering corundum grains at high temperatures. At the same time, these bricks have low porosity, high density, and good chemical stability, which makes corundum brick resist corrosion in acidic and alkaline environments.

Fused cast corundum bricks are refractory materials that are manufactured through the fusion of high-purity corundum or alumina in electric arc furnaces. These refractory bricks have exceptional heat resistance and mechanical strength. In addition, these bricks have wide applications.

According to raw materials

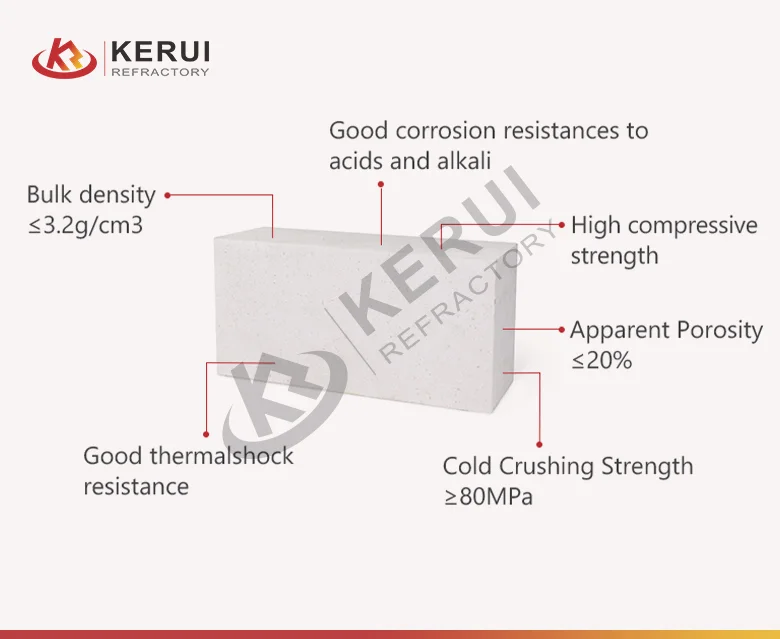

Properties of Kerui Corundum Bricks

The fire brick has excellent resistance to high temperatures. Therefore, they can withstand temperatures exceeding 1800°C (3272°F) or even higher, which makes them widely use in furnaces, kilns, incinerators, and other high-temperature industrial processes.

These refractory bricks have low porosity and high density. Their dense structure minimizes heat transfer, reduces energy consumption and improves overall thermal efficiency in industrial processes such as ceramic, glass, and steel.

These fire bricks for sale have good wear resistance, which enables them to withstand the corrosive forces during production. As a result, this property is particularly beneficial in applications such as ladle linings.

These fire bricks have exceptional chemical stability, which makes them resistant to chemical attack from acids, alkalis, and other corrosive substances. So these properties are important in industries such as petrochemicals, steelmaking, and glass.

The refractory bricks possess high mechanical strength, to ensure their structural integrity even under thermal stress and mechanical loads. Thus, this property allows them to withstand the physical demands of industrial environments such as steel and ladle linings.

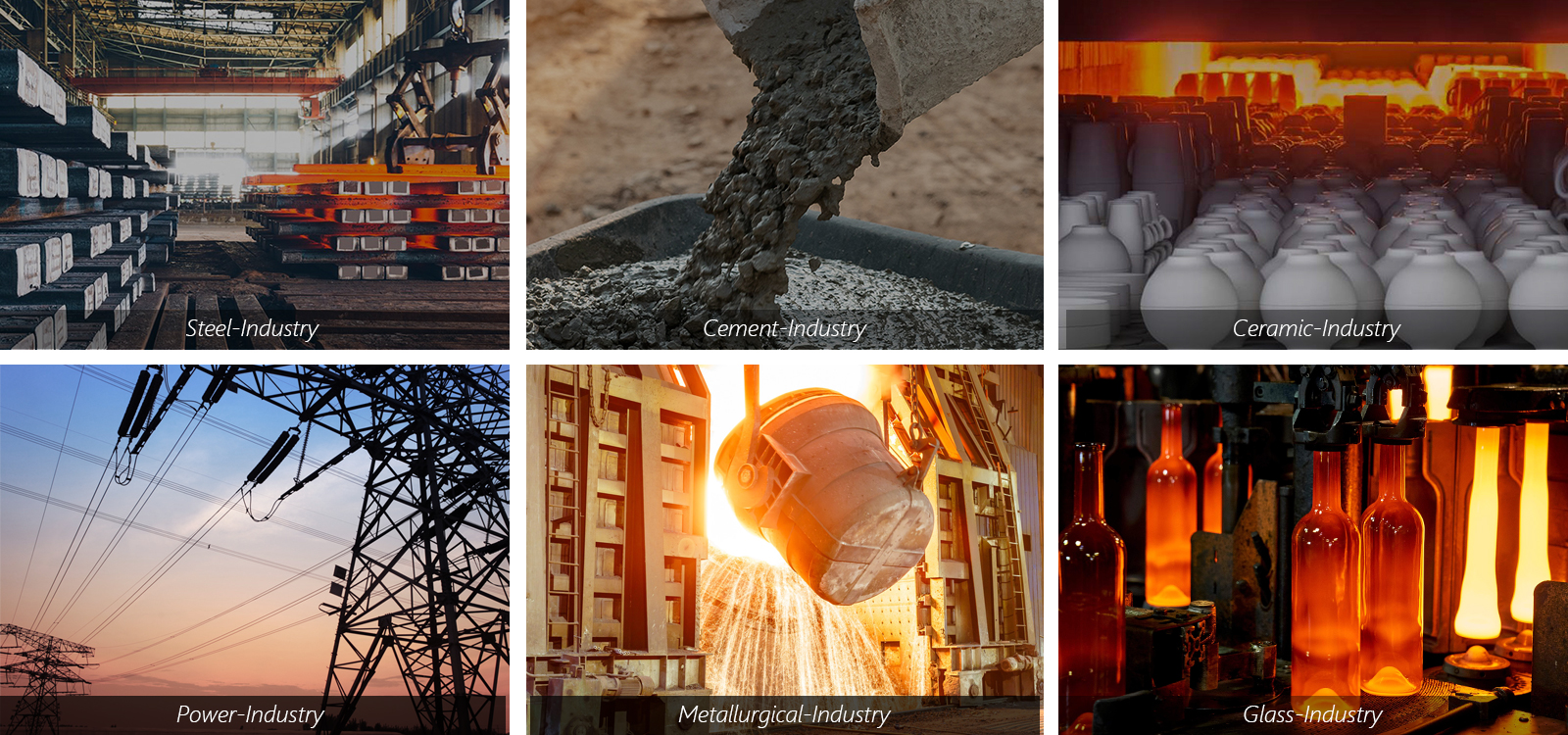

Application of Kerui Corundum Bricks

For buyers, it is very important to konw about the uses of refractory bricks. Here are some specific applications of corundum refractory bricks:

- Steel Industry: These refractory bricks are extensively employed in the steel industry for lining steel ladles, tundishes, and other equipment used in steelmaking processes. Because these refractory in steel industry provide excellent thermal resistance, chemical stability, and mechanical strength required to withstand the conditions of steel production.

- Glass Industry: The fire bricks are used in the construction of glass melting furnaces, regenerators, and tank linings. Meanwhile, their high temperature resistance, thermal shock resistance, and corrosion resistance make them ideal for maintaining stable and efficient glass production processes.

- Petrochemical Industry: In the petrochemical industry, refractory bricks are utilized in various high-temperature units such as reforming furnaces, cracking furnaces, and ethylene crackers. These bricks offer excellent resistance to thermal stress, chemical corrosion.

- Incineration and Power Generation: These bricks are used in incinerators and boilers. They provide effective thermal insulation, resistance to chemical attack and thermal shock resistance. Thus, the bricks can offer efficient and reliable operations in waste incineration and power generation plants.

- Non-Ferrous Metal Industry: These fire bricks are used in non-ferrous metal smelting processes, which include aluminum, copper, and zinc production. Meanwhile, they have common usage in crucibles, furnaces, and other equipment that require high-temperature resistance and excellent thermal stability.

Price of Kerui Corundum Bricks

The price of Kerui corundum bricks can vary based on several factors, such as specific type of corundum refractory brick, order quantity, customization requirements, and market conditions:

Different types of refractory bricks, such as white corundum fire bricks, or chrome corundum bricks, may have varying costs, which can affect their price. While prices can vary, choosing the right type is crucial to ensure cost-effectiveness over the long term.

The quantity of refractory bricks ordered can have an impact on the price. Bulk orders often attract discounts or lower price of refractory bricks compared to smaller orders. Therefore, it is necessary to understand the discounts the suppliers may offer.

If buyers require specific customization, such as non-standard shapes, sizes, or compositions, it can affect the prices. Customized corundum bricks may involve additional processing steps or raw material selection, which can impact the overall cost.

Market conditions can influence the price of refractory bricks, such as supply and demand dynamics, raw material availability, and manufacturing costs. Fluctuations in energy costs or raw material prices can affect the final product price.

How to Select A Reliable Corundum Brick Manufacturer?

As a manufacturer of refractory materials for more than 20 years, Kerui Refractory has rich experience in the production and export of corundum bricks. Meanwhile, it has sold refractory products to more than 30 countries such as Russia, Korea, Iran, Philippines, Turkey, Algeria, Pakistan, Brazil, Italy, etc. If you are looking for a reliable corundum bricks manufacturer, contact us!