Alumina Bricks

Kerui alumina bricks are refractory materials with excellent performance. Prices for alumina refractory bricks start at US$130 per ton or US$0.51 per block. In addition, we will have bigger discounts for customers who buy in bulk. Now, the promotion is in progress, welcome to call us!

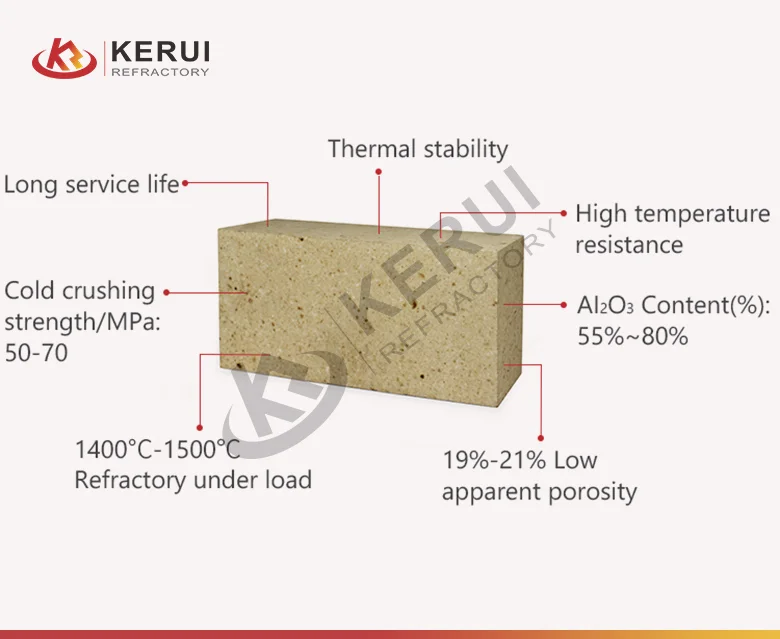

- Al2O3(≥) :48% – 80%

- Cold Crushing Strength:40MPa – 60MPa

- Refractoriness Underload:1420℃ – 1530℃

- Apparent Porosity:19% – 26%

Physical and Chemical Indicators of Alumina Bricks

| Item/Grade | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-55 | LZ-48 | LZ-75G | LZ-65G | LZ-55G | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 80 | 75 | 70 | 65 | 55 | 48 | 75 | 65 | 55 | |

| σ | 1.5 | ||||||||||

| Apparent Porosity/% | μ0 ≤ | 21 (23) | 24 (26) | 24 (26) | 24 (26) | 22 (24) | 22 (24) | 19 | 19 | 19 | |

| σ | 1.5 | ||||||||||

| Cold Crushing Strength/MPa | μ0 ≥ | 70 (60) | 60 (50) | 55 (45) | 50 (40) | 45 (40) | 40 (35) | 65 | 60 | 50 | |

| Xmin | 60 (50) | 50 (40) | 45 (35) | 40 (30) | 35 (30) | 30 (35) | 55 | 50 | 40 | ||

| σ | 15 | ||||||||||

| 0.2MPa Refractoriness Underload/℃ | μ0 ≥ | 1530 | 1520 | 1510 | 1500 | 1450 | 1420 | 1520 | 1500 | 1470 | |

| σ | 13 | ||||||||||

| Permanent Linear Change/% | Xmin Xmax | 1500℃*2h -0.4~0.2 | 1450℃*2h -0.4~0.1 | 1500℃*2h -0.2~0.1 | 1450℃*2h -0.2~0 | ||||||

Alumina Refractory Bricks Properties

Alumina fire bricks are the common refractory materials. Their main component is aluminum oxide (Al2O3), with an aluminum content between 48% and 99%. Its main properties include:

- High temperature resistance: high alumina bricks can withstand high temperature environments and can usually withstand temperatures above 1500 degrees Celsius. Moreover, some special types of high alumina bricks, such as super alumina refractory, can even withstand higher temperatures.

- Corrosion resistance: alumina firebrick has good resistance to corrosion by acid, alkali and some other chemical substances. Therefore, it has a long service life in some corrosive environments.

- Good thermal shock resistance: the high alumina refractory has good thermal shock resistance. It can maintain good stability in environments with rapid temperature changes and is not prone to cracking and breakage.

- High strength: alumina refractory have high compressive strength and flexural strength and can withstand certain mechanical loads and vibrations.

- Wear resistance: some high alumina bricks have wear-resistant particles added to the formula and have super wear resistance. Such as wear-resistant high alumina refractory. Therefore, you can use them in some work environments that require regular wear and tear. Such as hot metal ladle, converter furnace wall and other parts.

What Industrial Equipment Are Alumina Bricks Used in?

Kerui alumina bricks have good fire resistance and chemical stability. It has many uses in industrial production, including but not limited to the following aspects. You can send us a private message on Twitter to learn more about the application fields of high alumina refractory.

- High temperature kilns: you can use high alumina refractory to build various high-temperature kilns. Such as metallurgical furnaces, ceramic kiln, etc. Moreover, it can withstand chemical attack and thermal stress in high temperature environments. Therefore, it can be used in the construction of refractory brick walls, furnace roofs, furnace bottoms and furnace linings.

- Heat treatment equipment: you can use alumina refractory to build a variety of heat treatment equipment. Such as annealing furnaces, incinerators, etc. Using Kerui high alumina bricks, your equipment can heat treat, sinter or incinerate materials under high temperature conditions.

- Thermal power generation equipment: we can use alumina refractory as lining materials inside the boilers of thermal power plants. Because it can withstand the erosion of burning substances under high temperature and pressure and protect the boiler structure.

- Chemical equipment: Kerui alumina refractory can resist the erosion of chemical substances and corrosion under high temperature conditions. Therefore, in the chemical production process, we can use it to build various chemical equipment. Such as reactors, converters, etc.

- Glass industrial equipment: alumina firebrick refractory can also withstand the erosion and thermal stress of high-temperature glass liquids. So, in the glass manufacturing process, high alumina bricks can be used to build the lining and insulation layer of glass furnaces.

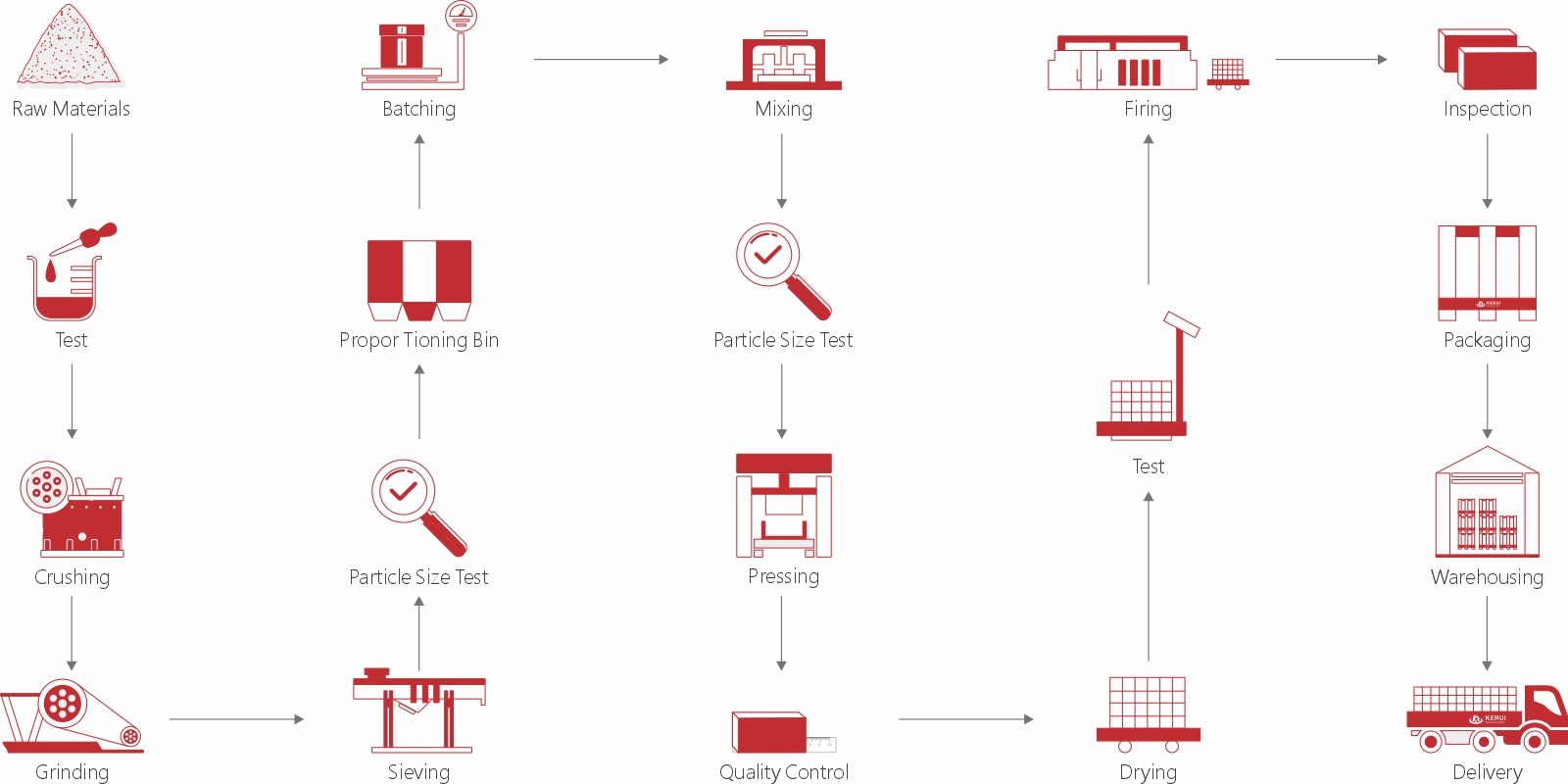

Alumina Bricks Manufacturing Process

The production process of alumina refractory starts with the preparation of raw materials. It includes a mixture of high-alumina bauxite, clay and calcined alumina, which is crushed and screened to obtain the appropriate particle size and ingredient ratio. Then, we mix the raw materials with a certain proportion of water to form a slurry and shape it through the mold. We then dry them in a drying chamber to remove the moisture. Subsequently, after high-temperature sintering, the chemical components in the raw materials react to form a dense ceramic material. Finally, we package and store the finished products to ensure product quality and safety for use.

Kerui strictly controls the temperature, time and material ratio of each link during the entire production process. Therefore, we can ensure the production of refractory bricks, insulation bricks and cheap refractory cement with stable quality and excellent performance.

Kerui Has High Quality Alumina Fire Bricks for Sale

Prices at a Good Value

The starting price of Kerui high alumina refractory is US$130 per ton or US$0.51 per block, which is very competitive in the high-quality high alumina brick market. Kerui Company has reduced production costs by optimizing the production process. We then translate this advantage into favorable prices, allowing customers to purchase high quality alumina bricks and silicon refractory at affordable prices.

Alumina Bricks with High Quality Composition

The high quality composition of alumina bricks means it has excellent fire resistance, wear resistance and corrosion resistance. Therefore, we select high quality raw materials and adopt advanced production processes to ensure the stable composition and excellent quality of refractory fire bricks. In other words, customers can safely choose the high alumina bricks provided by Kerui Company.

Long Service Life

After careful design and selection of high quality materials, the alumina firebricks and high alumina insulation brick produced by Kerui Company can be used for two to three years. Moreover, long service life means customers can reduce the frequency of replacement and maintenance. This significantly reduces operating costs and downtime and improves production efficiency and stability.

Timely After-Sales Service

Kerui company has a professional after-sales service team that can promptly respond to customer needs and provide technical support, maintenance and consulting services. Whether you encounter problems during product use or need product upgrades and replacements, Kerui can respond quickly and provide solutions. Therefore, Kerui ensures that customers can maintain production continuity.

Conclusion

Choosing Kerui alumina bricks means choosing high quality, reliability and economical practicality. As professional alumina brick manufacturers in China, we have five major factories: heavy brick factory, light brick factory, unshaped refractory material factory, ceramic fiber products factory and fused-cast brick factory. We are committed to providing you with high quality high temperature refractory materials! If you need it, please feel free to contact us!