Refractory Mortar for Sale

If you are looking for the best refractory mortar suppliers in China, please get to know about Kerui Refractory. Kerui refractory mortar for sale has wide usage in high-temperature industries for its excellent heat resistance, thermal shock resistance and chemical resistance. Here are more details.

- Al2O3 (%) :40-78

- Fe2O3 (%) :0.7-1.2

- Classification Temperature (℃) :1300-1600

- Refractoriness Underload (℃) :1320 – 1600

Kerui Refractory Mortar for Sale

Kerui refractory mortar is a type of mortar suitable for use in high-temperature environments. It usually consists of a mixture of heat-resistant materials, such as refractory aggregates, binders and additives. Kerui refractory company mortar for sale is used to bond and seal refractory bricks or other heat-resistant materials, to provide structural integrity and prevent heat leakage. The best mortar for firebrick plays an important role in maintaining the efficiency and longevity of high-temp equipment.

What are The Types of Kerui Refractory Mortar?

Refractory mortar from Kerui Refractory is a special type that is used to withstand high temperatures and for applications involving fire, heat or thermal stress. As one of the famous refractory bricks suppliers, KERUI has different types of refractory mortars, each suitable for specific temperature ranges and applications.

Unique Advantages of Kerui Refractory Mortar

Kerui Refractory Mortar utilizes high-quality raw materials and advanced manufacturing processes to ensure superior product performance. Moreover, it has excellent adhesion, thermal shock resistance and chemical resistance, which improves the overall efficiency of the refractory lining.

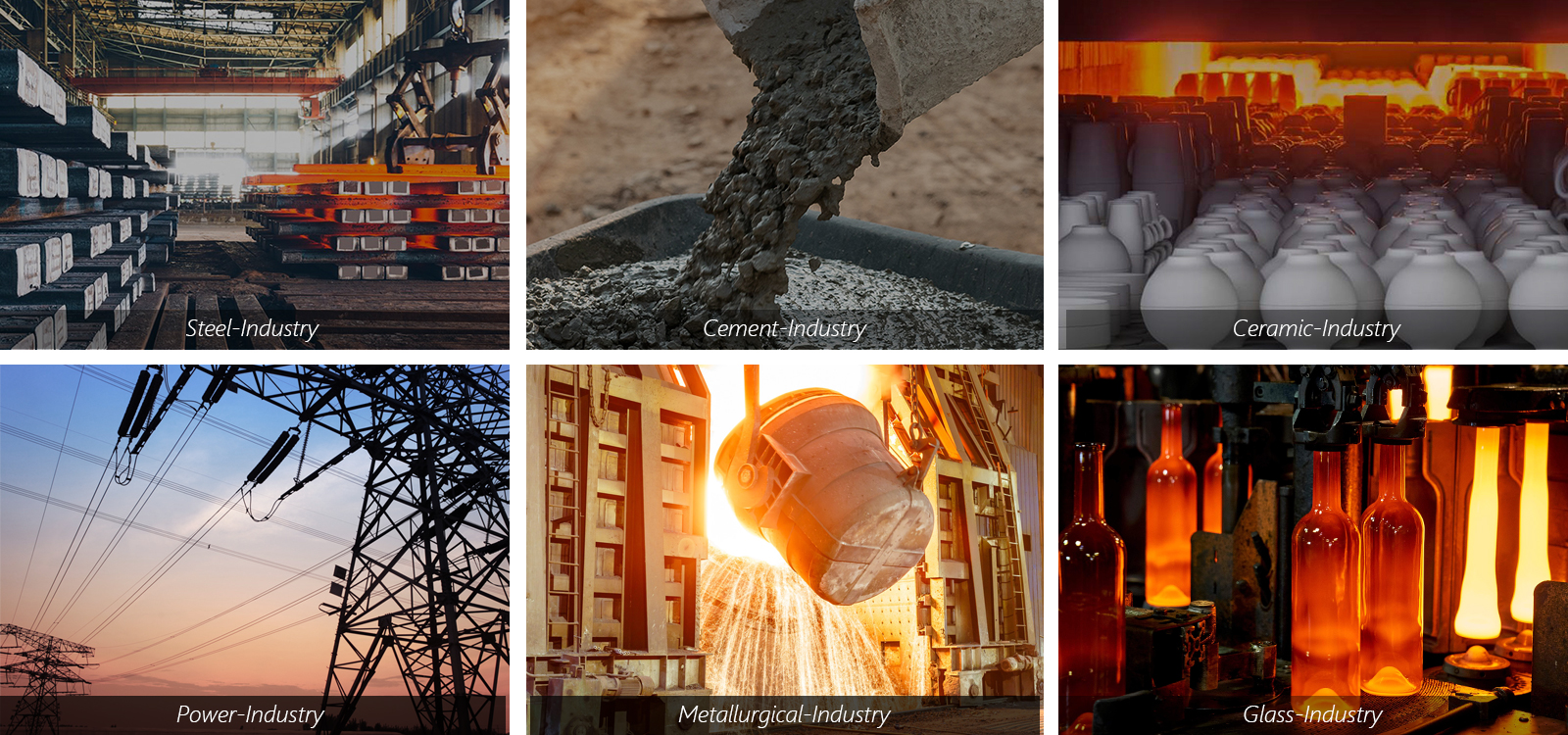

Due to its excellent performance, Kerui refractory mortar is suitable for steel, cement, glass, ceramics, petrochemical and other industries. What’s more, it can also be used in industrial kilns, furnaces, incinerators, chimneys, and other kinds of high-temperature equipment.

Owing to high-quality recipes, Kerui refractory mortar for sale provides long-lasting and durable refractory linings. In addition, the mortar is able to withstand high temperatures and harsh environments, to ensure longer service life and less frequent maintenance.

In the long run, choosing Kerui refractory mortar is cost-effective. Meanwhile, its durability and resistance to abrasion reduce equipment replacement and repair, save maintenance costs and downtime, and increase productivity. When purchasing wet or dry refractory mortar, it is important to focus on refractory brick price as well as other aspects of its value.

Kerui offers customized solutions to meet specific customer requirements. Therefore, we can customize the composition and properties of mortar to adapt to different temperature ranges and chemical environments, based on the needs of customers’ construction.

Different Applications of Refractory Mortar

Refractory mortar and refractory cement play a vital role in many industries, and they provide the necessary strength, heat resistance, and chemical stability. Some common applications are:

The Process of Making Mortar

When you buy refractory mortar, fire bricks, and insulation bricks, you should pay attention to their production process. Kerui can guarantee the quality in every production process. In addition, the specific steps for making refractory mortar may vary slightly based on the type of refractory mortar produced, but the general process is as follows:

Tips for Proper Storage of Refractory Mortar

Proper storage of refractory mortar and refractory castable for sale is essential to maintain its quality. Here are some tips to ensure the effective storage of refractory mortar:

If the refractory mortar is water-based, protect it from freezing temperatures, which can alter its properties and render it ineffective. So keep it in a temperature-controlled area to avoid freezing.

Ensure that the original packaging of the refractory mortar is sealed securely to protect it from moisture. Besides, if the packaging appears damaged, transfer the mortar to a moisture-proof container and seal it.

Refractory mortar is sensitive to moisture, because wet refractory mortar will affect its performance. Thus, store dry refractory mortar away from any source of water or moisture. Ideally, store it in a climate-controlled environment.

Place the containers of refractory mortar on pallets or raised surfaces to avoid direct contact with the floor. Therefore, this prevents moisture absorption from the ground and allows for better air circulation around the containers.

How to Choose a Suitable Refractory Mortar Supplier?

Look for refractory mortar suppliers who have a proven track record in the industry for delivering high-quality refractory mortar and soft fire bricks. Besides, experience is an very important sign of their expertise and reliability.

Ask about the supplier’s quality control certifications. Meanwhile, reputable refractory mortar suppliers should adhere to international quality standards and have strict testing procedures to ensure consistent product quality.

Depending on your unique needs, suppliers that offer customized refractory mortar solutions can meet your requirements. What’s more, they can formulate mortars to suit your temperature range and application method.

A reliable supplier should provide technical support and guidance to help you select the right refractory mortar for your application. At the same time, they should provide professional advice based on your specific requirements.

As a professional refractory mortar manufacturer, Kerui will be your reliable partner. So. if you want to get high-quality refractory mortar, contact us now! You can also contact us on Pinterest.