Magnesia Carbon Bricks

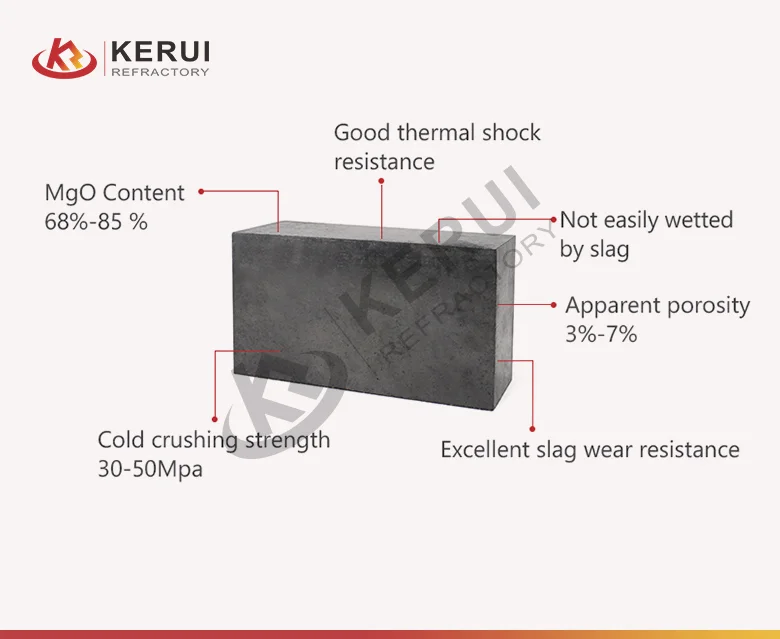

Magnesia carbon bricks are a composite refractory material. It effectively utilizes the strong resistance to slag erosion of magnesia and the high thermal conductivity and low expansion of carbon. In addition, its use makes up for the shortcomings of magnesia’s poor resistance to peeling.

- MgO(≥): 69% – 85%

- C (≥): 5% – 18%

- Bulk Density: 2.87g/cm³ – 3.15g/cm³

- Cold Crushing Strength: 30MPa – 50MPa

Magnesia Carbon Bricks Specification

| Item/Grade | Apparent Porosity/% | Bulk Density (g/cm³) | Cold Crushing Strength/MPa | High-temperature Bending Strength (1400℃*0.5h)/MPa | ω (MgO)/% | ω (C)/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| μ0 ≤ | σ | μ0 ≥ | σ | μ0 | σ | μ0 ≥ | σ | μ0 ≥ | σ | μ0 ≥ | σ | |

| MT-5A | 5.0 | 1.0 | 3.10 | 0.05 | 50.0 | 10.0 | / | / | 85.0 | 1.5 | 5.0 | 1.0 |

| MT-5B | 6.0 | 1.0 | 3.02 | 0.05 | 50.0 | 10.0 | / | / | 84.0 | 1.5 | 5.0 | 1.0 |

| MT-5C | 7.0 | 1.0 | 2.92 | 0.05 | 45.0 | 10.0 | / | / | 82.0 | 1.5 | 5.0 | 1.0 |

| MT-5D | 8.0 | 1.0 | 2.90 | 0.05 | 40.0 | 10.0 | / | / | 80.0 | 1.5 | 5.0 | 1.0 |

| MT-8A | 4.5 | 1.0 | 3.05 | 0.05 | 45.0 | 10.0 | / | / | 82.0 | 1.5 | 8.0 | 1.0 |

| MT-8B | 5.0 | 1.0 | 3.00 | 0.05 | 45.0 | 10.0 | / | / | 81.0 | 1.5 | 8.0 | 1.0 |

| MT-8C | 6.0 | 1.0 | 2.90 | 0.05 | 40.0 | 10.0 | / | / | 79.0 | 1.5 | 8.0 | 1.0 |

| MT-8D | 7.0 | 1.0 | 2.87 | 0.05 | 35.0 | 10.0 | / | / | 77.0 | 1.5 | 8.0 | 1.0 |

| MT-10A | 4.0 | 0.5 | 3.02 | 0.03 | 40.0 | 10.0 | 6.0 | 1.0 | 80.0 | 1.5 | 10.0 | 1.0 |

| MT-10B | 4.5 | 0.5 | 2.97 | 0.03 | 40.0 | 10.0 | / | / | 79.0 | 1.5 | 10.0 | 1.0 |

| MT-10C | 5.0 | 0.5 | 2.92 | 0.03 | 35.0 | 10.0 | / | / | 77.0 | 1.5 | 10.0 | 1.0 |

| MT-10D | 6.0 | 0.5 | 2.87 | 0.03 | 35.0 | 10.0 | / | / | 75.0 | 1.5 | 10.0 | 1.0 |

| MT-12A | 4.0 | 0.5 | 2.97 | 0.03 | 40.0 | 10.0 | 6.0 | 1.0 | 78.0 | 1.2 | 12.0 | 1.0 |

| MT-12B | 4.0 | 0.5 | 2.94 | 0.03 | 35.0 | 10.0 | / | / | 77.0 | 1.2 | 12.0 | 1.0 |

| MT-12C | 4.5 | 0.5 | 2.92 | 0.03 | 35.0 | 10.0 | / | / | 75.0 | 1.2 | 12.0 | 1.0 |

| MT-12D | 5.5 | 0.5 | 2.85 | 0.03 | 30.0 | 10.0 | / | / | 73.0 | 1.2 | 12.0 | 1.0 |

| MT-14A | 3.5 | 0.5 | 2.95 | 0.03 | 38.0 | 10.0 | 10.0 | 1.0 | 76.0 | 1.2 | 14.0 | 1.0 |

| MT-14B | 3.5 | 0.5 | 2.90 | 0.03 | 35.0 | 10.0 | / | / | 74.0 | 1.2 | 14.0 | 1.0 |

| MT-14C | 4.0 | 0.5 | 2.87 | 0.03 | 35.0 | 10.0 | / | / | 72.0 | 1.2 | 14.0 | 1.0 |

| MT-14D | 5.0 | 0.5 | 2.81 | 0.03 | 30.0 | 10.0 | / | / | 68.0 | 1.2 | 14.0 | 1.0 |

| MT-16A | 3.5 | 0.5 | 2.92 | 0.03 | 35.0 | 8.0 | 8.0 | 1.0 | 74.0 | 1.2 | 16.0 | 0.8 |

| MT-16B | 3.5 | 0.5 | 2.87 | 0.03 | 35.0 | 8.0 | / | / | 72.0 | 1.2 | 16.0 | 0.8 |

| MT-16C | 4.0 | 0.5 | 2.82 | 0.03 | 30.0 | 8.0 | / | / | 70.0 | 1.2 | 16.0 | 0.8 |

| MT-18A | 3.0 | 0.5 | 2.89 | 0.03 | 35.0 | 8.0 | 10.0 | 1.0 | 72.0 | 1.2 | 18.0 | 0.8 |

| MT-18B | 3.5 | 0.5 | 2.84 | 0.03 | 30.0 | 8.0 | / | / | 70.0 | 1.2 | 18.0 | 0.8 |

| MT-18C | 4.0 | 0.5 | 2.79 | 0.03 | 30.0 | 8.0 | / | / | 69.0 | 1.2 | 18.0 | 0.8 |

Advantages and Properties of Magnesia Carbon Bricks

High-quality magnesium carbon bricks composition are usually composed of high-purity magnesia and carbon. Additionally, refractory brick manufacturers make it through mixing, pressing and high-temperature calcination. Therefore, its excellent performance makes it widely used in industrial fields.

- Excellent fire resistance: magnesia carbon refractory has excellent fire resistance because it contains a high proportion of magnesia and carbon. Therefore, it can withstand extreme conditions in high-temperature environments such as industrial applications such as steel smelting and glass manufacturing.

- High temperature stability: magnesite carbon bricks and can maintain stable performance at high temperatures and are not prone to ablation and deformation. Therefore, you can use it widely in the lining of high-temperature furnaces and other equipment.

- Good thermal conductivity: Kerui magnesia carbon bricks have a low thermal conductivity and can effectively insulate. So, this helps maintain temperature stability in the furnace and improves thermal energy utilization efficiency. Besides, magnesite carbon bricks can be used together with refractory castable cement.

- Strong corrosion resistance: magnesite carbon bricks can resist many chemical attacks, such as alkaline and acidic substances. Therefore it is also widely used in the chemical industry.

- Good mechanical properties: our magnesia carbon bricks have high compressive strength and earthquake resistance. It can withstand a certain degree of mechanical shock and vibration to ensure the stable operation of the equipment.

- Good plasticity: Kerui magnesium carbon bricks are easy to process into various fire brick shapes and sizes to adapt to the needs of different equipment. That is to say, this increases construction flexibility and efficiency.

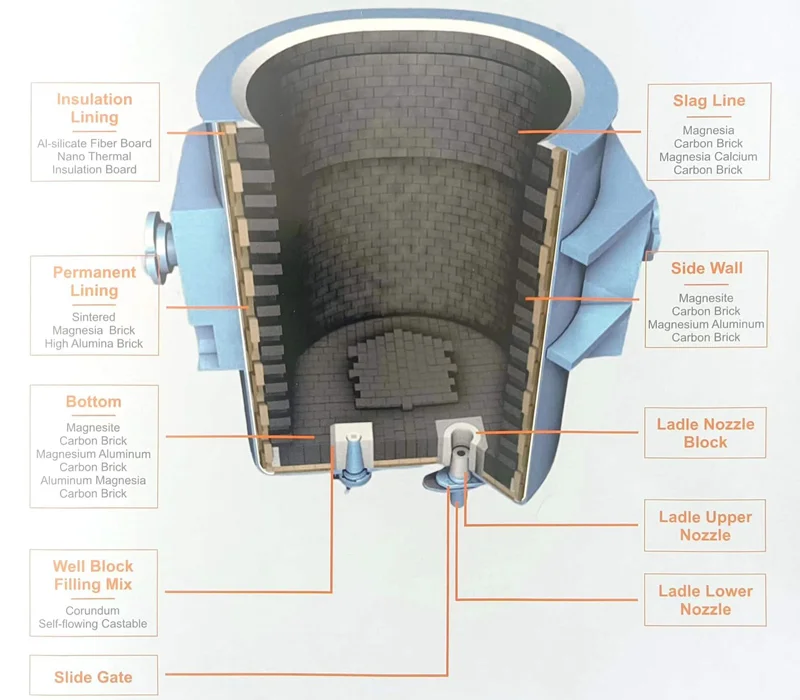

Magnesia Carbon Bricks Uses

Magnesia carbon bricks are widely used in high-temperature environments that require fire resistance, wear resistance and corrosion resistance in industry, mainly including:

Iron and steel smelting equipment: used as a blast furnace lining, converter lining plate and slag line of ladle. It can withstand the erosion of high temperature and corrosive gases and protect the furnace body from damage.

- Glass manufacturing equipment: as lining for glass furnaces. It can withstand the erosion of high-temperature glass liquid and maintain the stability and durability of the furnace body.

- Chemical industry equipment: used for lining of chemical equipment, pipelining, etc. Moreover, magnesite refractory bricks has excellent corrosion resistance and can resist chemical attack such as acid and alkali.

- Aluminum electrolysis cell: it can withstand high temperatures and chemical corrosion, extending equipment life and increasing production efficiency. Therefore, you can use it as the cathode plate of an aluminum electrolytic cell.

- Electric furnace and electric arc furnace: used as lining of AC electric arc furnace and DC electric arc furnace. Moreover, it can withstand high temperature and the influence of electromagnetic fields, protecting the furnace body from damage.

- Other high-temperature equipment: such as oil refining equipment, boilers and kilns of thermal power plants, etc.

How to Find High-Quality Magnesia Carbon Bricks

Reputable Refractory Manufacturer

Look for reputable refractory fire brick manufacturers with a track record of producing high-quality products. Moreover, these refractory bricks manufacturers typically employ strict quality control measures to ensure consistent performance and reliability.

Supplier Recommendations

You can also seek advice from industry professionals, consultants or colleagues with experience with magnesia carbon bricks. Or you can contact Kerui directly for free help. Their insights can help you identify vendors known for delivering high-quality products.

Online Refractory Market

Explore online platforms dedicated to refractory materials, such as the official websites of Alibaba and Kerui. Kerui offers a wide selection and detailed product specifications, allowing you to compare and select high-quality fire proof bricks.

Trade Show

Attend industry-specific trade shows where refractory manufacturers showcase their products. It provides the opportunity to interact directly with suppliers, learn about their manufacturing processes and evaluate the quality of their refractory materials.

Why Kerui Magnesia Carbon Bricks Stand Out?

As the core components of refractory material, the quality of magnesia and carbon is crucial. Kerui magnesia carbon bricks use high-purity raw materials, carefully selecting high-quality electric magnesium ore and high-purity magnesium oxide. In addition, we also use finely processed high-quality natural graphite or synthetic carbon materials. Therefore, we guarantee the stability and fire resistance of magnesia carbon bricks.

Through advanced production technology and strict quality control, Kerui maintains consistently high standards in the magnesite carbon bricks manufacturing process. Moreover, from raw material processing to finished product processing, every step of Kerui has been carefully designed and strictly monitored. So, we can ensure the excellent performance of magnesite carbon bricks and insulation bricks.

Through close cooperation with customers and continuous market research, Kerui can provide customized solutions for different industries and fields. We can meet the specific needs of our customers and continuously improve and optimize product performance to adapt to changing market needs. Besides, you can also find us on Twitter or leave a message directly in the message box to get free technical support.

Conclusion

By purchasing Kerui’s high-performance magnesia carbon bricks or insulating refractories, you can save long-term costs in equipment operation to a great extent. Besides, if you have questions about the physical and chemical indicators of magnesia carbon refractory, please contact us for a free consultation.