Alumina Silica Brick

Kerui provides customers with reliable alumina silica brick. So, we can ensure the stable and efficient operation of industrial production. Besides, stable and reliable refractory materials are the cornerstone of the normal operation of kilns.

- Price Advantage: located in Xinmi, the hometown of refractory materials, with abundant resources and affordable prices.

- After-Sales Advantage: one-on-one tracking service; technical support provided by the chief engineer.

- Supply Advantage: customized bricks are delivered from the kiln in 3-7 days and standard bricks are shipped directly from stock.

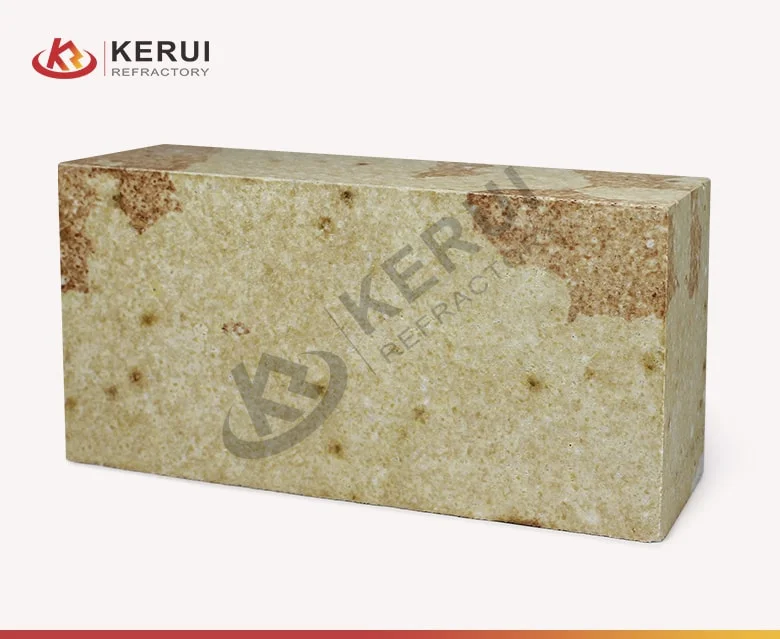

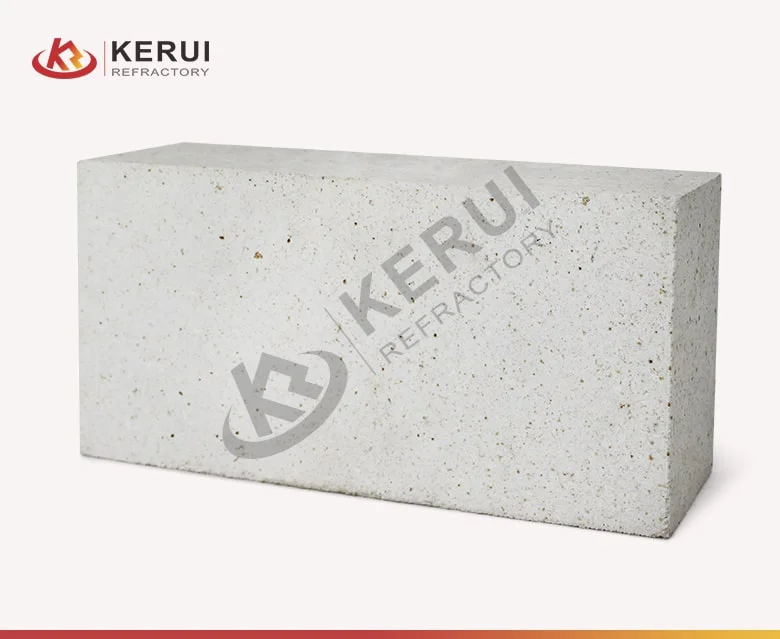

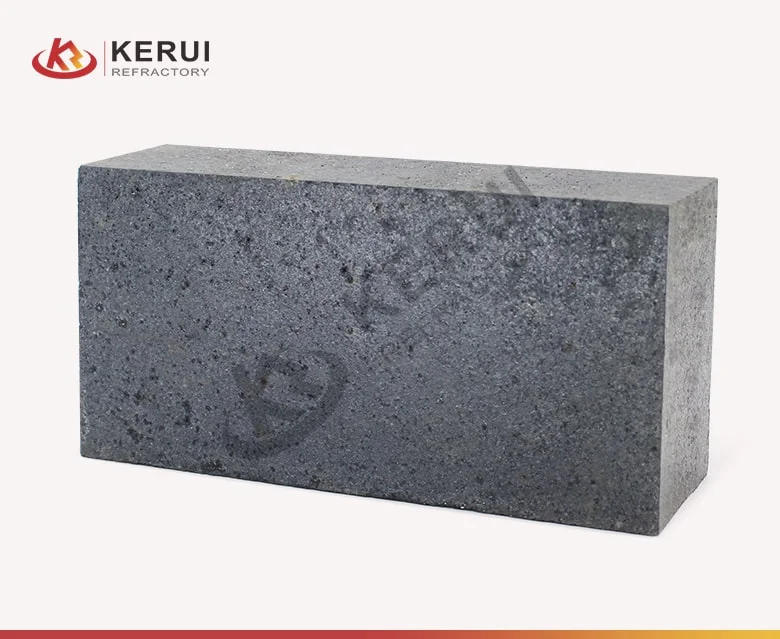

Main Classification of Alumina Silica Brick

Application of Alumina Silica Brick

Such as you can widely use Kerui Refractory the excellent high alumina bricks for lining steel-making electric furnaces, glass melting furnaces and cement rotary furnaces.

We can also mainly divide it into clay refractory bricks for blast furnaces, clay refractory bricks for hot blast furnaces and large clay refractory bricks for coke ovens and glass kilns.

You also can mainly use our high quality silica bricks as structural materials for coke ovens, glass furnaces, acid steelmaking furnaces and other thermal equipment.

You also can use it in hot blast furnace tops, blast furnace shafts and bottoms, glass melting furnace regenerators, ceramic sintering kilns, dead-end furnace linings in petroleum cracking systems.

Such as used in iron-making blast furnaces and hot blast furnaces, steel-making furnace external refining furnaces, glass melting furnaces and petrochemical industrial furnaces.

It is used as refractory material for high temp and erosion resistant kilns such as glass industrial pool kilns, glass electric kilns, slides in the steel industry and kilns in the soda ash industry.

Andalusite bricks with excellent performance can also fully meet the requirements for use in different parts of blast furnaces and hot blast stoves and in different working environments.

Sillimanite refractory materials are also widely used in glass kilns, blast furnaces, ceramics, etc. in metallurgy, chemical industry, building materials and other industries.

We also use it for making non-ferrous metallurgical retorts, aluminum casting molds, electric furnace linings, aluminum electrolytic cell linings and ceramic kiln furniture.

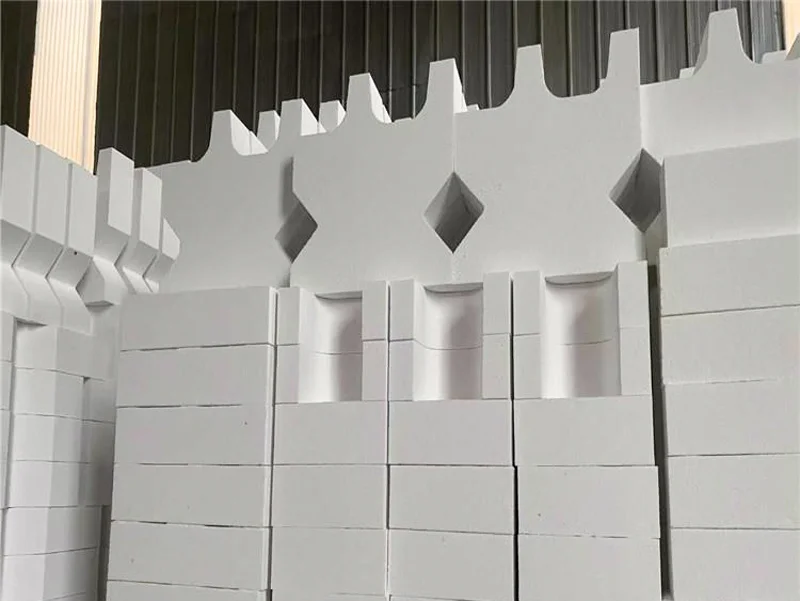

Kerui has a Full Series of Alumina Silica Fire Brick for Sale

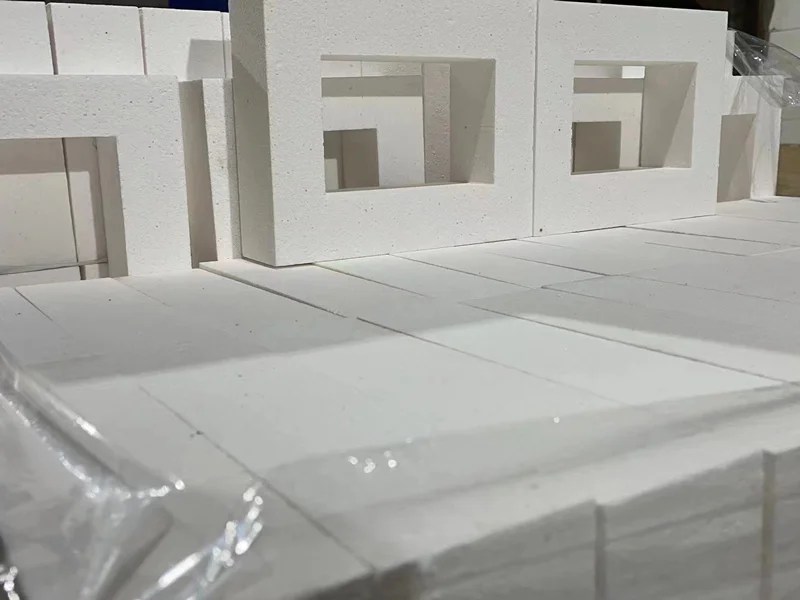

Kerui pays attention to every detail. So, from the selection of raw materials to the inspection of finished products, we ensure the stability and reliability of product quality. Therefore, each of our fire bricks and high heat ceramic meets the highest standards.

We also use advanced production processes. This such as includes raw material formulation, molding, drying, sintering and other links. In addition, our craftsmen are professionally trained to carefully make each alumina silica refractory brick.

Kerui also has invested a lot of money and resources in the construction of modern production facilities. Moreover, our production lines are carefully designed to meet customer orders of different sizes and needs with high-efficiency production.

Kerui uses meticulous planning and effective coordination to maximize production efficiency and refractory brick quality. Besides, we rationally allocate resources to ensure the stability of raw material supply and the normal operation of production lines.

Guide to Buying Alumina Silica Refractory Brick

Understand the Needs

Before buying alumina silica fire brick for sale, you need to understand the specific usage requirements. Such as this includes the use temperature, working environment and chemical erosion. Therefore, you can choose the right type of refractory bricks through it.

Choose the Right Material

Choose fire brick and brick insulation with the right proportion of alumina and silica content according to the specific use environment. High alumina bricks are suitable for more demanding environments, while silica bricks are suitable for relatively mild environments.

Pay Attention to Product Quality

Choose aluminum silicon refractory bricks produced by regular manufacturers to ensure stable product quality and performance. Such as take Kerui as an example. We have product test reports and relevant certifications. Moreover, it meets industry standards.

Consider After-Sales Service

Choose a fire bricks manufacturers that provides comprehensive after-sales service. This way you also can get technical support and solutions in time when you encounter problems during use. What’s more, Kerui provides a one-stop comprehensive service.

Conclusion

As a leader in the field of alumina silica brick, Kerui also adheres to the principle of “quality first, customer first”. Moreover, we continue to innovate and progress to provide customers with better quality and more reliable alumina-silicon refractory brick products and services. In addition, you can also watch more videos about our refractory brick production process on Kerui’s YouTube homepage.